Wave Soldering Machine WSM 350 DF (Finger Type)

Product Details:

- Operating Voltage 110-215 Volt (V)

- Usage Industrial

- Material Stainless Steel

- Size Standard Sizes

- Product Type Wave Soldering Machine

- Coating yes

- Click to View more

Wave Soldering Machine WSM 350 DF (Finger Type) Price And Quantity

- 1100000 INR/Number

- 1 Number

Wave Soldering Machine WSM 350 DF (Finger Type) Product Specifications

- Industrial

- yes

- Stainless Steel

- Standard Sizes

- Wave Soldering Machine

- 110-215 Volt (V)

Wave Soldering Machine WSM 350 DF (Finger Type) Trade Information

- 5-10 Days

Product Description

Overview of Wave Soldering Machine WSM 350 DF (Finger Type)

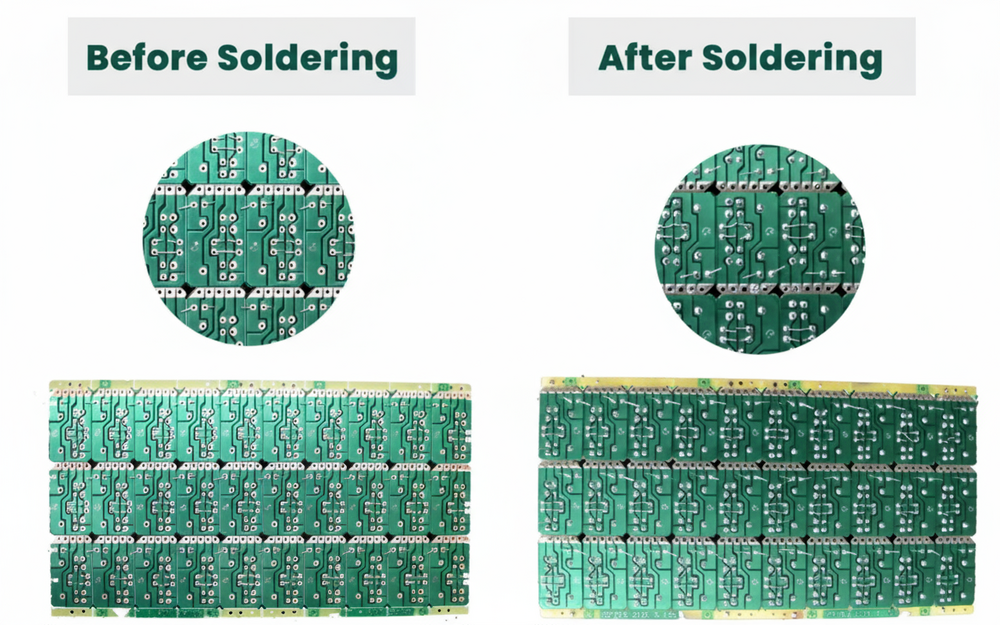

Built with dual wave solder baths, advanced spray fluxing with large preheater, and an integrated cooling fans, the WSM 350 DF is the ultimate solution for high volume, lead free, and defect free PCB soldering. Its robust design, energy efficiency, and low maintenance features make it a preferred choice across industries like automotive, consumer electronics, telecommunications, and industrial automation.

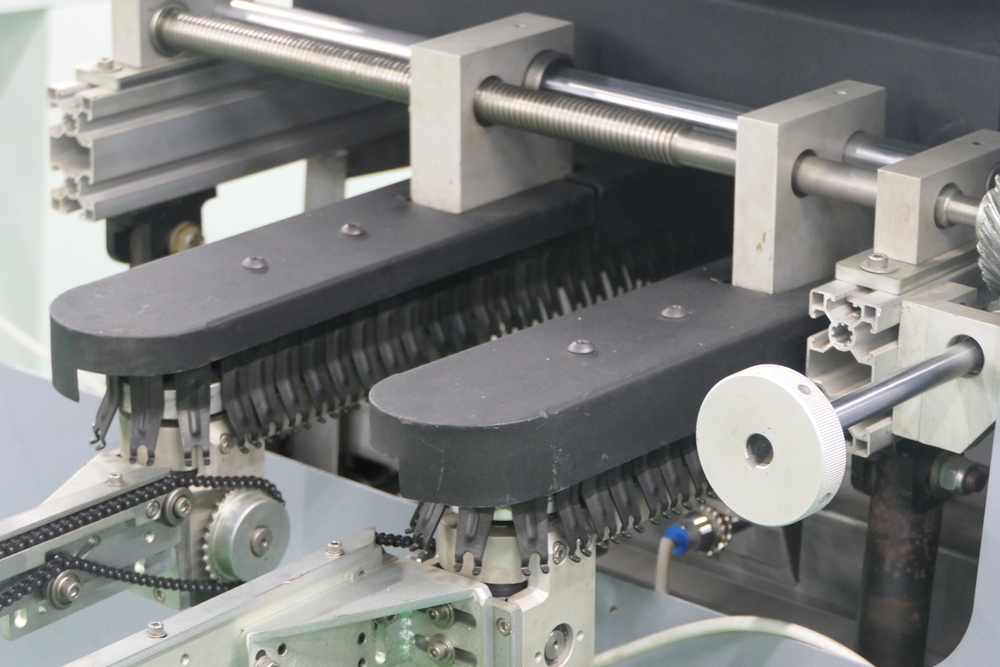

- Fully Automatic Operation: Chain conveyor with Special Steel fingers ensures seamless inline PCB soldering without manual handling.

- Dual Wave Solder Bath with Advanced Fluxing: spray fluxing, preheater, and dual wave solder bath guarantee defect free solder joints for mass production.

- High Reliability & Low Maintenance: Self cleaning system, lead free solder compatibility, and robust design deliver long term performance with reduced downtime.

TechnicalSpecificationsof Wave Soldering Machine 350 DF (Finger Type)

| Parameters | Value | ||

| General | |||

| Model | WSM 350 DF | ||

| Wave Type | Dual Wave Finger Type | ||

| Total Finger in Chain Conveyor | 1400 | ||

| Wave Width | 360 mm | ||

| Wave Height | 0-8 mm | ||

| Start-up Power | 13 kW | ||

| Operating Power | 7 kW | ||

| Cooling System | 2 Air Fan cooling | ||

| Control System | Touch Screen + PLC | ||

| Power Supply | 440V AC, 50Hz, 3 Phase, 5 wires | ||

| Weight | 580 Kg | ||

| Dimensions | 3400 1280 1750 mm | ||

| Spray Fluxer Systems (Standard) | Foam Fluxer Systems (Optional) | ||

| Transmission | Stepping Motor | Candle Pipe | 2-10 micron |

| Spray Pressure | 0.25Mpa--0.4Mpa | Foam width | 20 mm |

| Flux Supply | Automatic (10100 ml/min) | Foam Height | 10 mm |

| Flux Capacity | 4 Ltr. | Flux Bath capacity | 4 Ltr. |

| Preheating System | |||

| Preheating Method | Heating Element | ||

| Control Mode | PID SSR | ||

| Preheating Zones / Length | 1200 mm | ||

| Pre Heater Power | 3.6 KW | ||

| Warm-up Time | 15 min (150C setting) | ||

| Conveyor System | |||

| PCB Width | 60 -350mm | ||

| Conveyor Speed | Max 2.5 m/min (Normal 0.8 mtr/min) | ||

| Conveyor Height | 750+/-20 (mm) | ||

| Finger | Special Steel withs hook (Optional: Titanium Finger) | ||

| Conveyor Angle | 48 | ||

| Soldering System | |||

| Solder Pot Trolley | Manual Mechanical Motor drive (Motorized Option) | ||

| Solder Pot Material | Special Steel high grade | ||

| solder pot temperature | Up to 300 | ||

| Solder Bath Power | 8.2 KW | ||

| solder pot capacity | 260 Kg | ||

| Air Consumption | |||

| Consumption | 4.0 cfm (30 PSI) | ||

| Pressure | 40 PSI | ||

Key Features of Wave Soldering Machine WSM 350 DF (Finger Type)

Dual Wave Soldering Technology

- Dual solder bath design improves throughput for high density boards.

- Advanced PLC + HMI Touchscreen Control System

- Digital control of conveyor speed, solder wave height, and temperature

- Energy Efficient PID + SSR Heating Control

- Reduces power consumption while ensuring stable soldering

- Spray Fluxing

- Compatible with RMA, RA, alcohol-based, low solids, and VOC-free fluxes.

- Foam Flux with Preheater

- Automatic Chain Conveyor with Special Steel fingers (Titanium Fingers Optional)

- High grade Special Steel fingers provide durability and precision.

- Compatible with linking conveyors, inline modules, and multi line setups.

- Special Steel Alloy Solder Pot for Lead Free Compatibility

- 260 kg solder capacity with temperature up to 300C

- Self Cleaning System

- Ensures stable solder wave quality and reduces dross formation.

- Flexible Solder Bath Options

- Optional motorized solder bath control for ease of operation.

- High grade RoHS compliance solder pot with PID control.

- Advanced Control System

- Touchscreen + PLC control with real time monitoring.

- VFD for conveyor speed and wave height adjustment.

- Precision Pneumatic Control with Pressure Gauge

- Allows for fine tuning of air pressure to ensure perfect flux application every time.

- Energy Efficient Heating

- PID + SSR controlled heating reduces power consumption.

- Integrated Cooling Fan

- Reduces stress, cracks, and warpage in PCBs after soldering.

- Automatic Chain Conveyor with Special Steel fingers (Titanium Fingers Optional)

Main Parts of Wave Soldering Machine WSM 350 DF

- Spray Fluxer System (Standard )

- Conveyor Width & Height AdjustmentControl PanelPLC Control SystemSelf-Cleaning Tool for FingersPneumatic System & Air Flow and Flux Flow control with Solenoid ValvePreheater System

-

Solder Bath (Dual Design)

Chain Conveyor with Special Steel fingers (Titanium Fingers Optional)

Applications of Wave Soldering Machine WSM 350 DF

PCB Assembly Lines Fully automatic soldering for inline mass production.

- Consumer Electronics TVs, radios, and home appliances with high-quality joints.

- Automotive Electronics Dashboards, ECUs, sensors, and control modules.

- Industrial Equipment Automation controllers, power supplies, and PCB boards.

- Telecommunication Devices Routers, switches, and networking equipment.

- Medical Electronics Precision diagnostic and healthcare devices.

Advantages of Wave Soldering Machine WSM 350 DF

- Automatic Operation Eliminates manual handling with inline conveyor.

- Faster Production Dual solder bath and inline design improve efficiency.

- Consistent Quality Titanium fingers ensure stable PCB handling.

- Energy Efficiency PID-controlled heating and optimized power use.

- Reduced Maintenance Self-cleaning system lowers downtime.

- Lead-Free Compatibility RoHS-compliant solder pot for future-proofing.

- Flexible Integration Compatible with linking conveyors and inline setups.

- High Reliability: Ensures defect-free soldering across industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free