Wave Soldering Machine WSM 200 SC (Carrier Type)

Product Details:

- Operating Voltage 110-215 Volt (V)

- Usage Industrial

- Material Stainless Steel

- Size Standard Sizes

- Product Type Wave Soldering Machine

- Color White

- Click to View more

Wave Soldering Machine WSM 200 SC (Carrier Type) Price And Quantity

- 1 Number

- 260000 INR/Number

Wave Soldering Machine WSM 200 SC (Carrier Type) Product Specifications

- Industrial

- Standard Sizes

- 110-215 Volt (V)

- White

- Stainless Steel

- Wave Soldering Machine

Wave Soldering Machine WSM 200 SC (Carrier Type) Trade Information

- 5-10 Days

Product Description

Wave Soldering Machine 200 SC (Carrier Type)

Overview

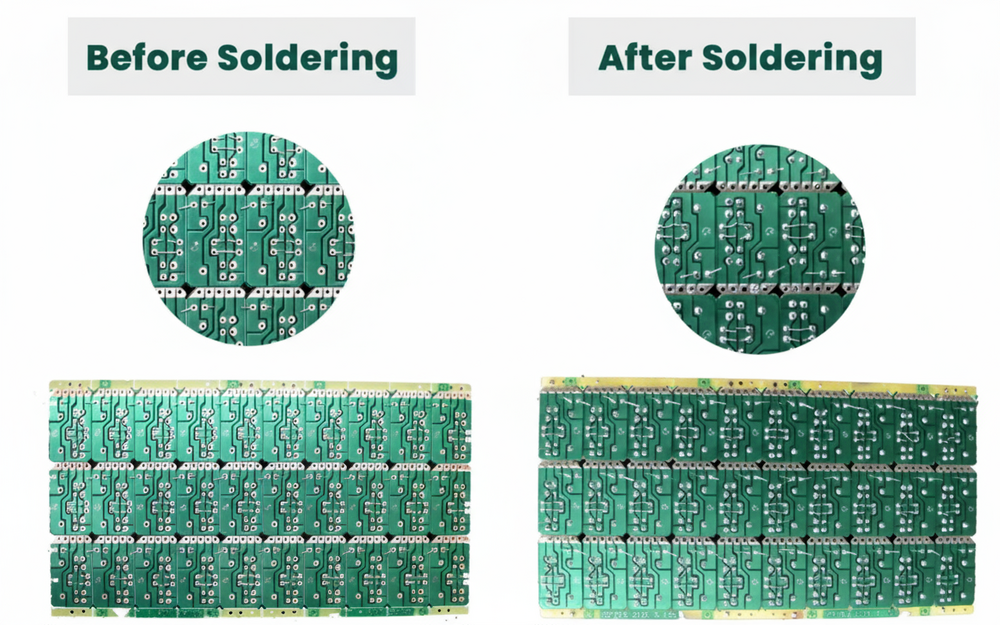

The Wave Soldering Machine 200 SC (Carrier Type) is a high-performance single-wave soldering system for PCB mass production. It delivers reliable soldering for through-hole and selective SMD components with consistent joints, high throughput, and minimal defects. With precise temperature control, robust conveyors, and titanium alloy solder pot, it supports lead-free processes. Ideal for automotive, consumer, telecom, industrial, and medical electronics.

Benefits

-

High Productivity: Faster throughput, reduced cycle times.

-

Consistent Quality: Defect-free joints, less human error.

-

Lead-Free Ready: Durable titanium solder pot.

Key Features

-

Single-Wave Tech: Reduces bridging/skips, ensures coverage.

-

PLC + HMI: Real-time monitoring, easy digital control.

-

PID + SSR Heating: Stable solder bath & preheaters, energy efficient.

-

Automatic Conveyor (200 mm): Smooth vibration-free PCB transport.

-

Foam Fluxer: 210 m candle with auto economy mode.

-

Titanium Solder Pot (215 kg, 300C): Corrosion-resistant, long life.

-

Ceramic Preheater (800 mm): Even heating, insulated for efficiency.

-

2 Air Fans Cooling: Prevents cracks, ensures durability.

-

Finger Cleaning System: Keeps contact clean, prevents contamination.

-

Pneumatic Control: Pressure gauge + solenoid valve for precise flux spraying.

Main Parts

-

Solder Bath: Steel, SMT/Lambda nozzles, PID + PLC control, reduced dross.

-

Pre-Heater: 800 mm ceramic zone, even heating, PID stable.

-

Fluxer & Knife: ROHS-compliant, economy mode, independent control.

-

Conveyor: Chain type, aluminium, AC motor + VFD.

-

PCB Carrier: Aluminium with steel/titanium fingers, adjustable.

-

Control Panel: PLC + HMI, VFD motors, MCBs & relays.

-

Pneumatic System: Gauge + solenoid valve for air/flux control.

Process Parameters

-

Preheating: Up to 85C to avoid thermal shock.

-

Wetting Time: Strong solder-pad adhesion.

-

Dwell Time: 24 s for reliable joints.

-

Soldering Time: 510 s defect-free soldering.

-

Cooling: Forced-air prevents cracks & stress.

Applications

-

PCB Lines: Reliable soldering at scale.

-

Consumer: TVs, gadgets, appliances.

-

Automotive: ECUs, dashboards, sensors.

-

Industrial: Power boards, automation systems.

-

Telecom: Routers, switches, modules.

-

Medical: Diagnostic & precision devices.

Advantages

-

Optimized speed for mass production.

-

Defect-free, consistent solder joints.

-

Low energy costs with PID heating.

-

Long-life solder pot (steel/titanium).

-

User-friendly PLC + HMI interface.

-

Reduced downtime & maintenance.

-

Supports varied PCB sizes/components.

-

Ensures durable, high-reliability joints.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free