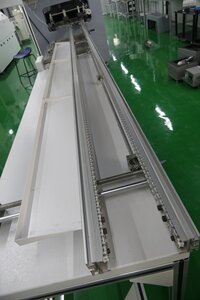

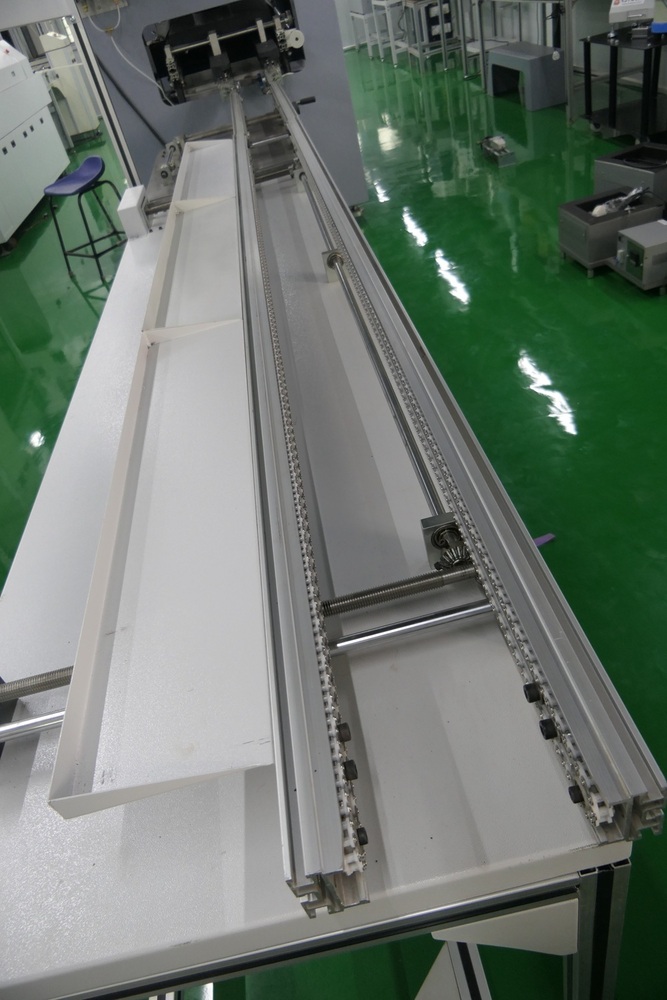

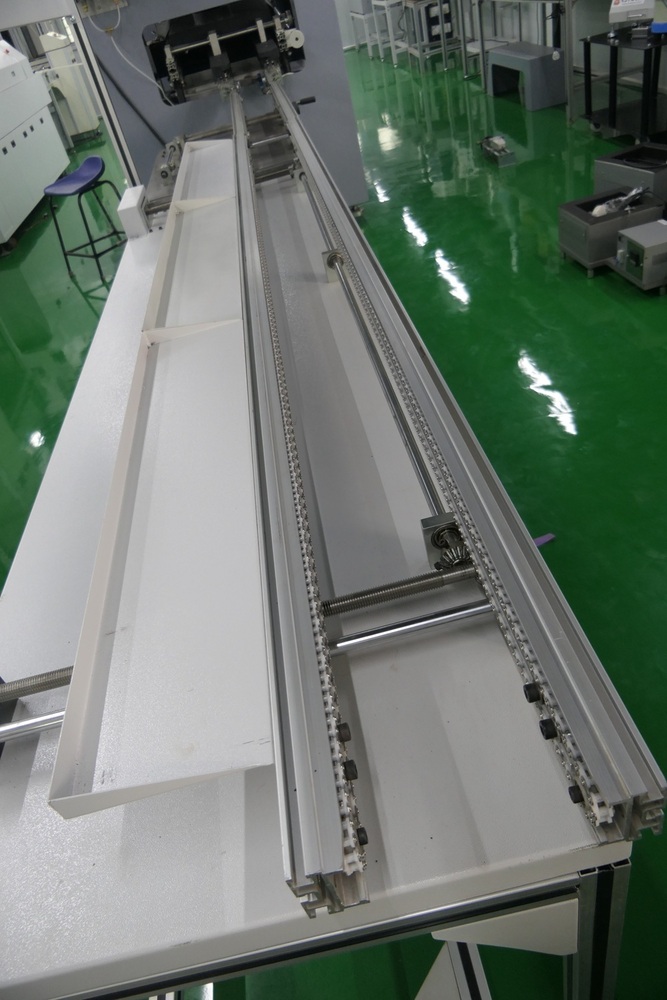

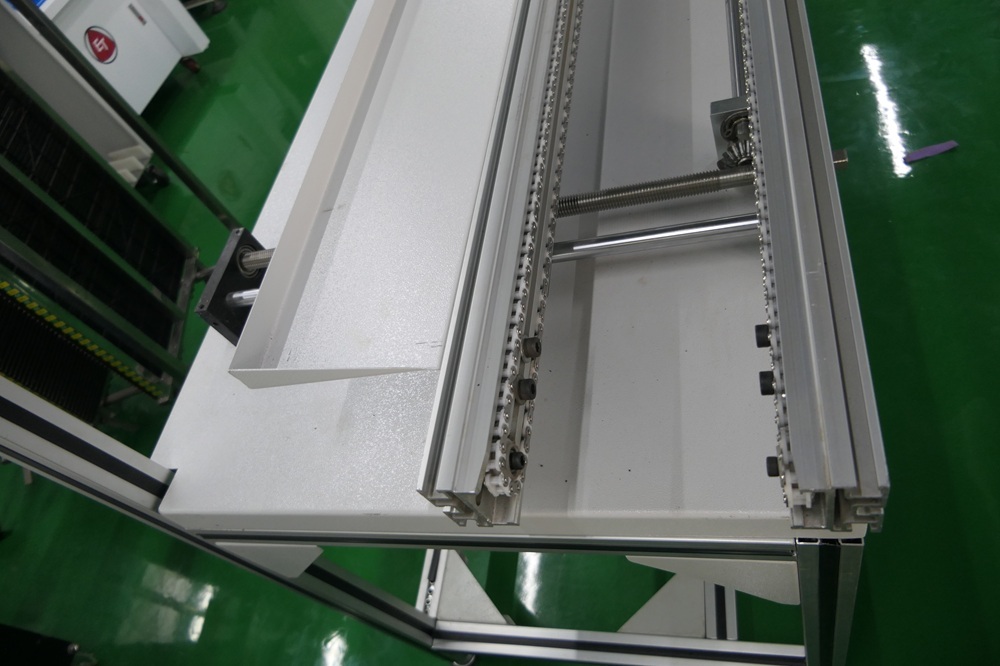

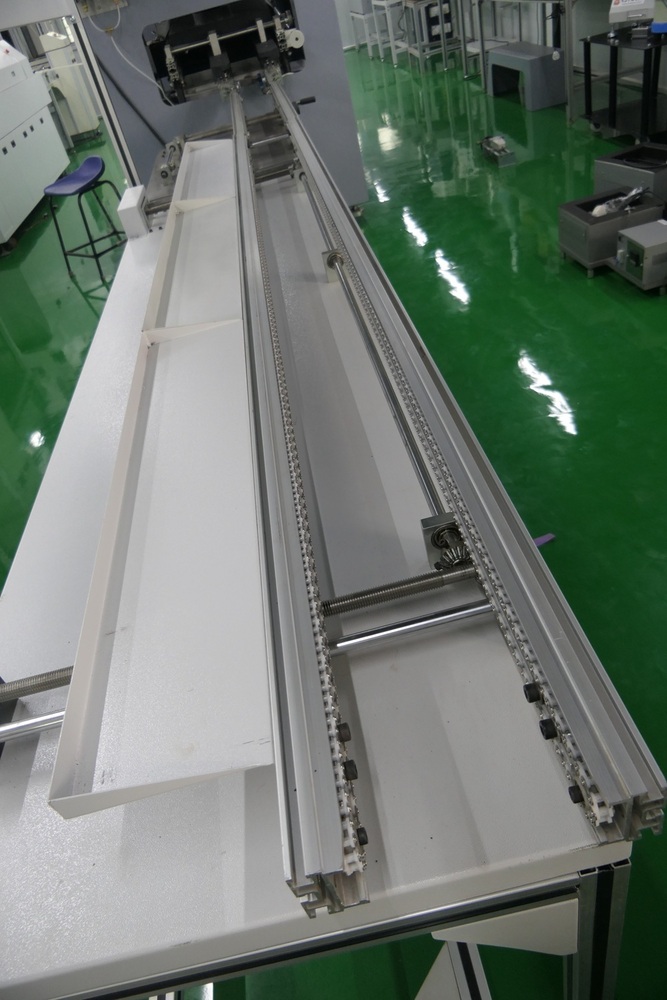

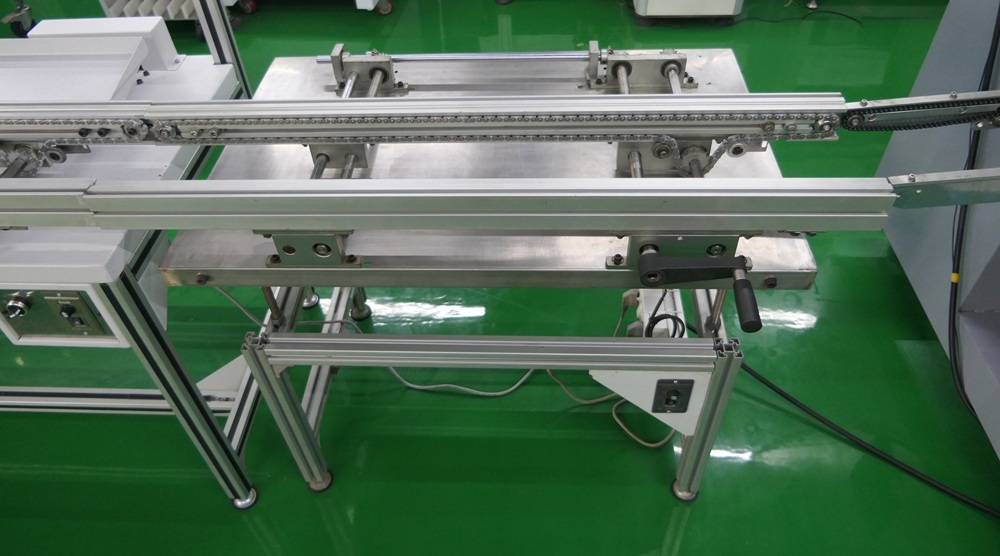

The MI Line Module 2.4 Mtr

62000 INR/Meter

Product Details:

- Features Good Quality

- Surface Finish Smooth

- Material MS

- Type Belt Conveyor

- Structure Chain

- Color Silver

- Voltage 110-215 Volt (v)

- Click to View more

X

The MI Line Module 2.4 Mtr Price And Quantity

- 1 Meter

- 62000 INR/Meter

The MI Line Module 2.4 Mtr Product Specifications

- Good Quality

- Chain

- 110-215 Volt (v)

- Silver

- Smooth

- MS

- Belt Conveyor

The MI Line Module 2.4 Mtr Trade Information

- 5-10 Days

Product Description

Technical Specifications| Parameter | Specification | ||||||||||||||||||

| Conveyor Type | Conveyor Length | Overall Width | Working Height | Total Height | PCB Width Range | Front Channel | Rear Channel | Structure | Conveyor Speed | Component Bins | Display Board | Motor Drive | Lighting | Voltage | Frequency | Material | Power Source | Automation Grade | Automatic |

Key Features

- Single-Side Operation for Maximum Efficiency

- Enables smooth PCB handling and manual component insertion from one side.

- Provides optimal working height (840 mm) to minimize operator fatigue and enhance productivity.

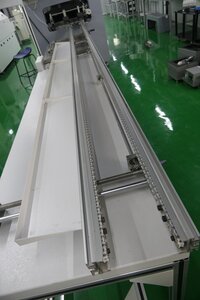

- Ergonomic & Adjustable Component Trays

- Features height-adjustable trays for organized component storage.

- Trays accommodate multiple PCB sizes for flexible and efficient assembly.

- Precision Variable Speed Control

- Gear motor with integrated AC speed control for consistent motion.

- Adjustable up to 3 m/min to match insertion, inspection, and wave soldering line speeds.

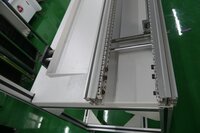

- Integrated Safety & Electrical Protection

- Equipped with emergency stop switches and power-failure interlock.

- Includes MCB protection and LED lighting for safe, well-lit operation.

- ESD-Safe Construction for Sensitive Components

- Uses anti-static materials to eliminate electrostatic discharge risk.

- Ensures product safety and compliance with international ESD standards.

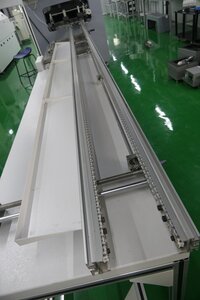

Applications

The MI Line Module supports multiple stages of PCB manufacturing, inspection, and handling, providing reliable performance in ESD-sensitive environments.

It ensures efficient material transfer between equipment, helping manufacturers maintain continuous production flow and high output quality.

- PCB Assembly & Manual Insertion Streamlines through-hole component placement during manual operations.

- PCB Testing & Inspection Lines Provides stable transfer during visual and electrical quality checks.

- Wave Soldering Preparation Transports populated PCBs directly to soldering systems.

- Integration with SMT/Automation Lines Works with pick-and-place machines, reflow ovens, and AOI equipment.

- High-Precision Manufacturing Ideal for automotive, medical, telecom, and consumer electronic assemblies.

Why Choose the MI Line Module 2.4 Mtr from Estovir Technologies

Estovir Technologies, with over 20+ years of expertise, delivers trusted PCB assembly and automation systems that meet modern manufacturing demands.

The MI Line Module is built for efficiency, scalability, and operator comfort, ensuring superior performance in every production setup.

- Proven Industry Experience Established in 2005, Estovir is a pioneer in PCB assembly automation.

- Customizable & Scalable Design Modular construction allows flexible line extensions (10 60 ft).

- High Productivity & Workflow Optimization Boosts efficiency by 15 % with reduced manual handling.

- Cost-Efficient & Low Maintenance Offers long service life with minimal downtime and energy use.

- Ergonomic & Safe Operation Optimized working height and ESD protection create a comfortable, risk-free workspace.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email