Semi Automatic Solder Paste Printer ET 680 SP

Product Details:

- Country Of Origin India

- Features Good Quality

- Control System Semi-Automatic

- Voltage 110-215 Volt (v)

- Surface Treatment Coated

- Warranty 1 year

- Usage & Applications Industrial

- Click to View more

Semi Automatic Solder Paste Printer ET 680 SP Price And Quantity

- 195000.00 INR/Unit

- 1 Unit

Semi Automatic Solder Paste Printer ET 680 SP Product Specifications

- Coated

- 1 year

- India

- 110-215 Volt (v)

- Industrial

- Good Quality

- Semi-Automatic

Semi Automatic Solder Paste Printer ET 680 SP Trade Information

- 1000 Unit Per Day

- 1 Week

Product Description

Semi-Automatic Solder Paste Printer ET 680 SP

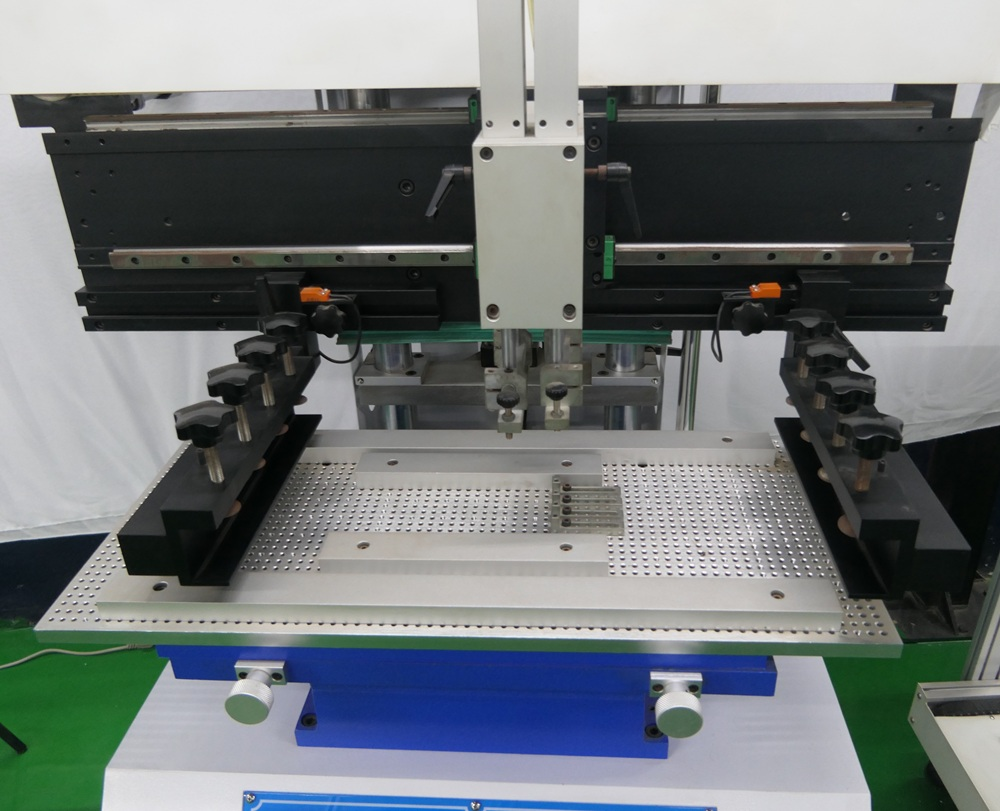

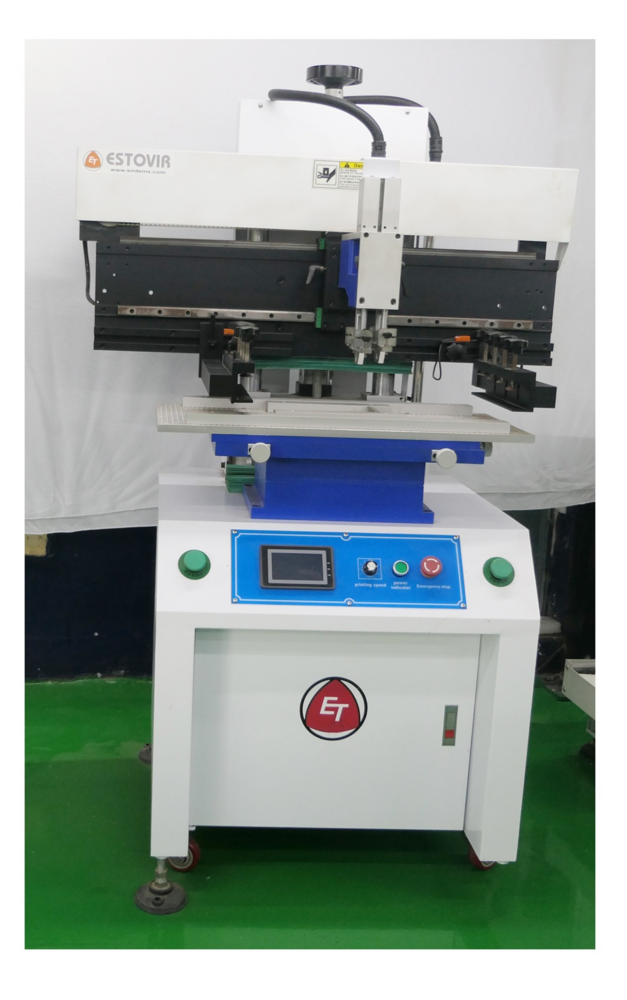

The Semi-Automatic Solder Paste Printer ET 680 SP by Estovir Technologies delivers exceptional PCB printing precision for medium- to high-volume electronics manufacturing. Powered by an advanced PLC Control System and intuitive touchscreen interface, it ensures stabilized, reliable performance and effortless operation for modern SMT lines.

The machine automatically sets and optimizes running parameters to suit various solder pastes and glues, guaranteeing consistent quality across different PCB types. Its high-rigidity linear-rail structure maintains printing stability and precision, while the flexible arming base and 45 rotatable squeegee holder enable quick setup, calibration, and maintenance. Designed for efficiency and repeatability, the ET 680 SP is the perfect blend of automation and accuracy for todays PCB production.

Technical Specifications

| Parameter | Specification |

| Model | ET 680 SP |

| Power Requirement | 220 V AC, 50 Hz, 1 Phase |

| Power Consumption | 100 W |

| PCB Thickness Range | 0.2 3.0 mm |

| Fine Adjustment of Platform | 0.05 mm |

| Printing Precision | 0.02 mm |

| Air Supply | 4 6 Kg/cm |

| Printing Platform | 350 500 mm |

| Stencil Dimension | 370 470 to 550 650 mm |

| PCB Dimension | 320 450 mm |

| PCB Positioning Method | Positioning Pin |

| Printing Method | Stencil Movement |

| Overall Dimension | 880 680 1650 mm |

| Weight | 220 Kg |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free