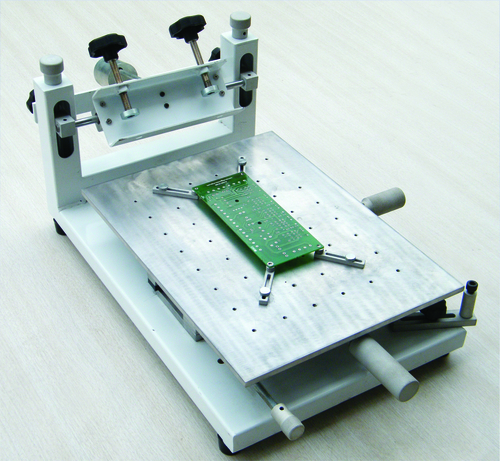

Semi-Automatic Solder Paste Printer ET 1200 SP

Product Details:

- Accuracy 0.01 mm

- Power Rating 220 VAC 10%, 50/60 Hz

- Lubricating System Manual lubrication

- Production Capacity Up to 700 cycles/hr

- Noise Level < 60 dB

- Machine Type Solder Paste Printer

- Motor Power Step Motor Driven

- Click to View more

Semi-Automatic Solder Paste Printer ET 1200 SP Price And Quantity

- 1 Number

Semi-Automatic Solder Paste Printer ET 1200 SP Product Specifications

- 1390 x 880 x 1650 mm

- Up to 700 cycles/hr

- Manual lubrication

- 0.01 mm

- 220 VAC 10%, 50/60 Hz

- White & Grey

- Step Motor Driven

- Semi-Automatic

- Semi-Automatic Solder Paste Printer

- PCB Solder Paste Printing

- Solder Paste Printer

- 280 kg

- < 60 dB

- Air cooled

- Anti-rust coating

- 220 W

- 220 V

- 10C 40C

- Universal Frame Holder

- ET 1200 SP

- Screen Printing

- 50/60 Hz

- Adjustable squeegee pressure, Quick stencil change, Emergency stop, Fine adjustment system

- Microprocessor-based digital control

- Stepper motor driven

- Electric

- Manual/Adjustable

Product Description

The Semi-Automatic Solder Paste Printer ET 1200 SP by Estovir Technologies is designed for high-precision and stable PCB solder paste printing in large-format and high-volume production lines. Engineered with an advanced PLC control system and touchscreen interface, it offers smooth operation, programmable control, and reliable print accuracy.

The machine automatically adjusts parameters based on solder paste or adhesive type, ensuring consistent and repeatable results. Its rigid linear-rail structure, flexible arming base, and 45 rotatable squeegee holder simplify setup and maintenance, providing unmatched performance for large PCB printing requirements.

Technical Specifications ET 1200 SP

Model: ET 1200 SP

PCB Thickness Range: 0.2 3.0 mm

Fine Adjustment of Platform: 0.05 mm

Printing Precision: 0.02 mm

Air Supply: 4 6 Kg/cm

Printing Platform: 350 1200 mm

PCB Dimension: 300 1200 mm

PCB Positioning Method: Positioning Pin

Printing Method: Stencil Movement

Power Requirement: 220V AC, 50Hz, 1 Phase

Power Consumption: 100W

Dimension: 1350 870 1650 mm

Weight: 280 Kg

Precision Engineering for Consistent Results

Engineered with microprocessor-based digital control and a universal frame holder, the ET 1200 SP delivers accurate solder paste application on every cycle. The automatic stencil positioning systemcomplemented by fine X/Y/ adjustmentensures each PCB is aligned precisely, reducing defects and improving overall product quality in demanding electronics assembly environments.

User-Friendly and Flexible Operation

The ET 1200 SP features an intuitive digital panel for easy parameter setting and a quick-change stencil system to streamline production switchovers. Its floating clamp fixture secures PCBs of various sizes, while caster wheels enable smooth mobility on the factory floor, enhancing operational flexibility and user convenience during high-volume manufacturing.

Durability and Enhanced Safety

Built with a rust-resistant coating and stainless steel squeegees, the printer withstands continuous operation in fluctuating ambient conditions. Safety is prioritized through an emergency stop switch, power cut-off protection, and a robust manual lubrication systemguaranteeing both the longevity of the equipment and the security of the operator throughout the production cycle.

FAQs of Semi-Automatic Solder Paste Printer ET 1200 SP:

Q: How does the ET 1200 SP ensure accurate solder paste placement on PCBs?

A: The ET 1200 SP uses a micrometer fine adjustment system for X, Y, and axes, coupled with an automatic stencil positioning system. This precision alignment, along with a universal frame holder and high-accuracy mechanics (0.01 mm), guarantees consistent and accurate solder paste deposition on every board.Q: What types of PCBs and stencil sizes are compatible with the ET 1200 SP?

A: This machine accommodates PCBs up to 1200 x 350 mm and supports stencils as large as 1250 x 400 mm, making it suitable for standard and large-format boards commonly used in SMT and electronics manufacturing applications.Q: Where can this solder paste printer be used effectively?

A: The ET 1200 SP is ideal for electronics manufacturing setups, especially Surface Mount Technology (SMT) lines where precision soldering is essential. Its features cater to environments requiring high throughput and reliability, such as contract manufacturing and PCB assembly plants.Q: What is the process for changing stencils on this printer?

A: The ET 1200 SP features a quick-change stencil mechanism, allowing operators to swap out stencils efficiently without laborious disassembly. The universal frame holder simplifies loading and securing different stencil types for uninterrupted production.Q: When is manual lubrication required for this equipment?

A: Manual lubrication should be conducted regularly based on the machines usage frequency and operating environment. This maintenance task helps ensure smooth movement of mechanical parts and extends the lifespan of the printer.Q: What are the main benefits of using a semi-automatic model like the ET 1200 SP?

A: Opting for a semi-automatic solder paste printer combines precision and control with operational efficiency. Users benefit from automated stencil alignment, customizable pressure settings, high repeatability, and reduced risk of operator errorresulting in better yield, less waste, and faster changeovers.Q: How is operator safety ensured during machine operation?

A: For enhanced safety, the ET 1200 SP incorporates an emergency stop switch and power cut-off protection. These features allow quick shutdown in case of anomalies and prevent potential hazards during maintenance or production, prioritizing operator well-being.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+