Reflow Oven Conveyorized 6 Zone

Product Details:

- Cooling System Forced Air Cooling

- Accuracy 1 C %

- Power Rating 7.5 kW

- Frequency 50 Hz Hertz (HZ)

- Lubricating System Automatic Lubrication

- Frame Type Sturdy Mild Steel Frame

- Motor Power 0.75 kW Kilowatt (kW)

- Click to View more

Reflow Oven Conveyorized 6 Zone Price And Quantity

- 6900000 INR/Unit

- 1 Unit

Reflow Oven Conveyorized 6 Zone Product Specifications

- 1 C %

- Automatic

- 380 V Volt (v)

- Forced Air Cooling

- RS232/USB

- 0.75 kW Kilowatt (kW)

- Reflow Oven Conveyorized 6 Zone

- Sturdy Mild Steel Frame

- Powder Coated

- Electric

- Room to 350 C Celsius (oC)

- 6 Heating Zones, Programmable Profile, Energy Efficient

- Approx. 900 Kilograms (kg)

- White and Blue

- 3400 x 720 x 1280 mm Millimeter (mm)

- Synchronous/Belt Drive

- 50 Hz Hertz (HZ)

- Conveyorized Reflow Oven

- <65 dB db

- RO-6Z

- 7.5 kW

- PCB Soldering for SMT Assembly

- Automatic Lubrication

- SMT (Surface Mount Technology)

Reflow Oven Conveyorized 6 Zone Trade Information

- 1 Unit Per Day

- 1 Week

Product Description

Reflow Oven Conveyorized 6 Zone

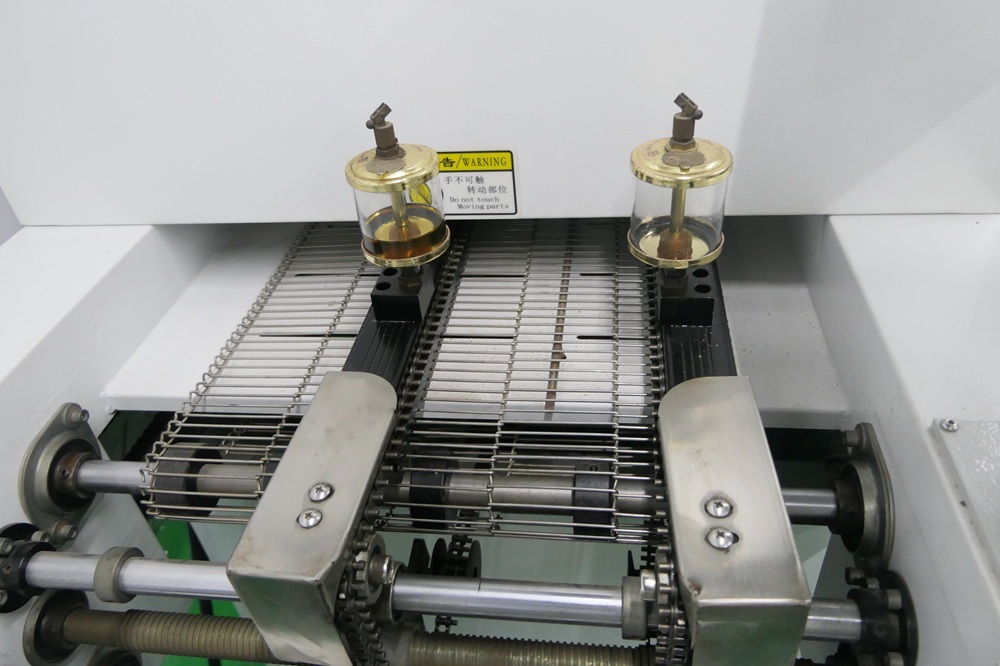

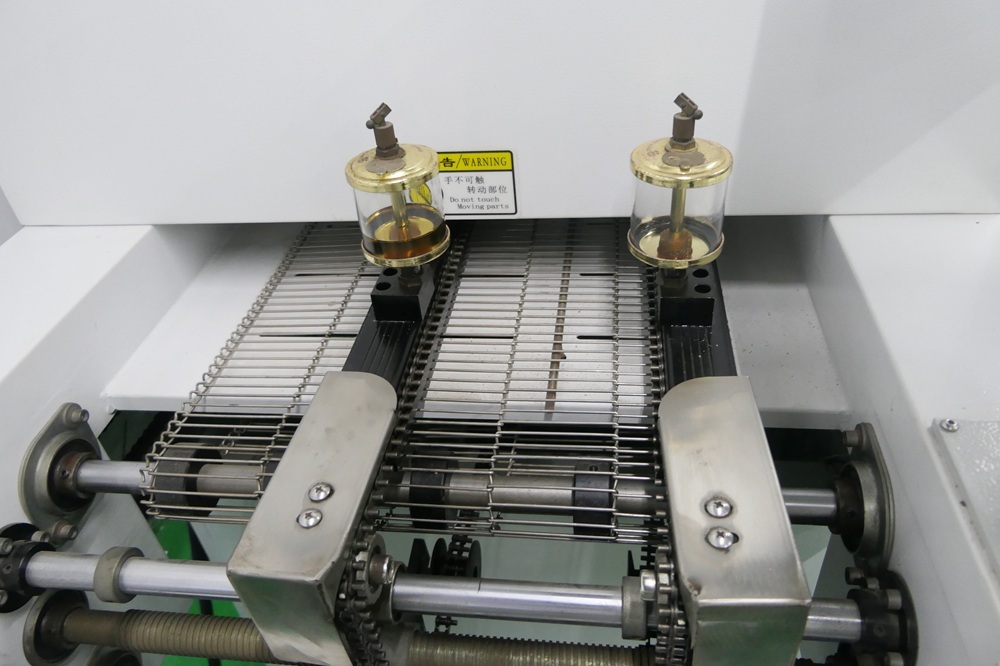

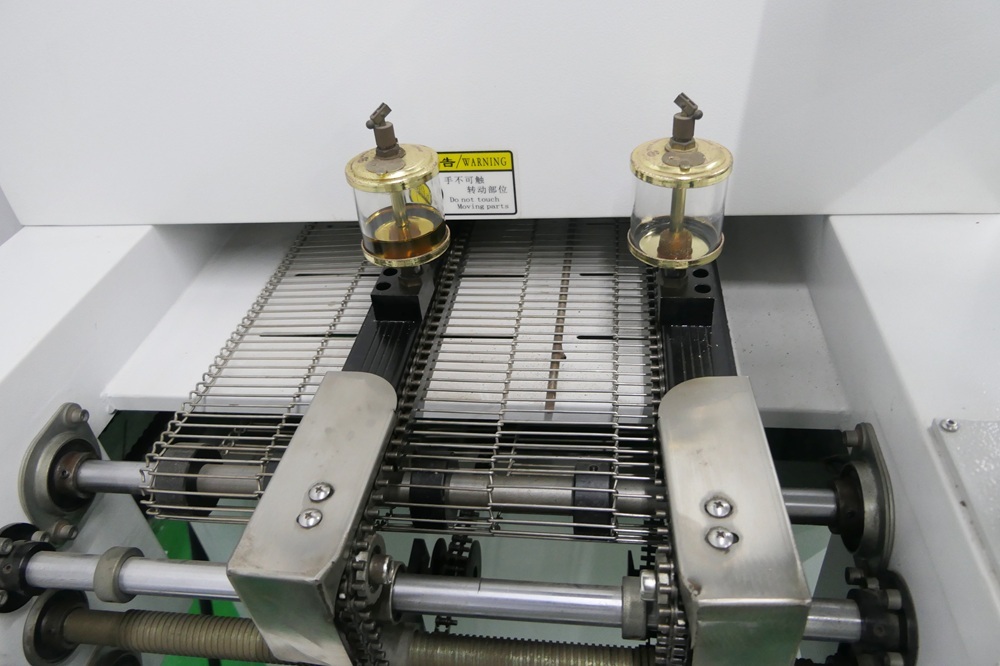

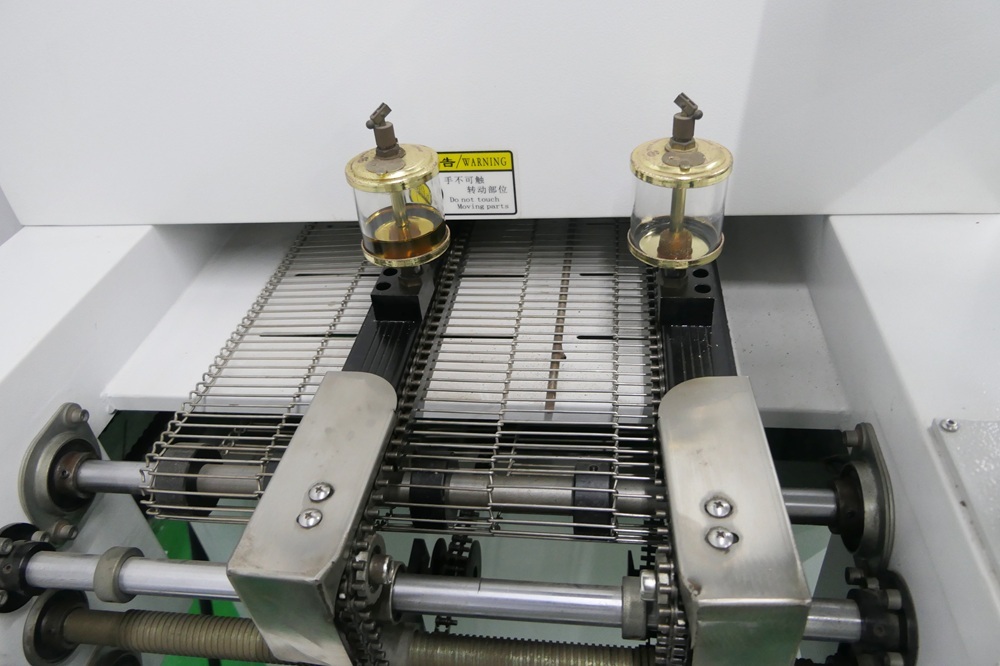

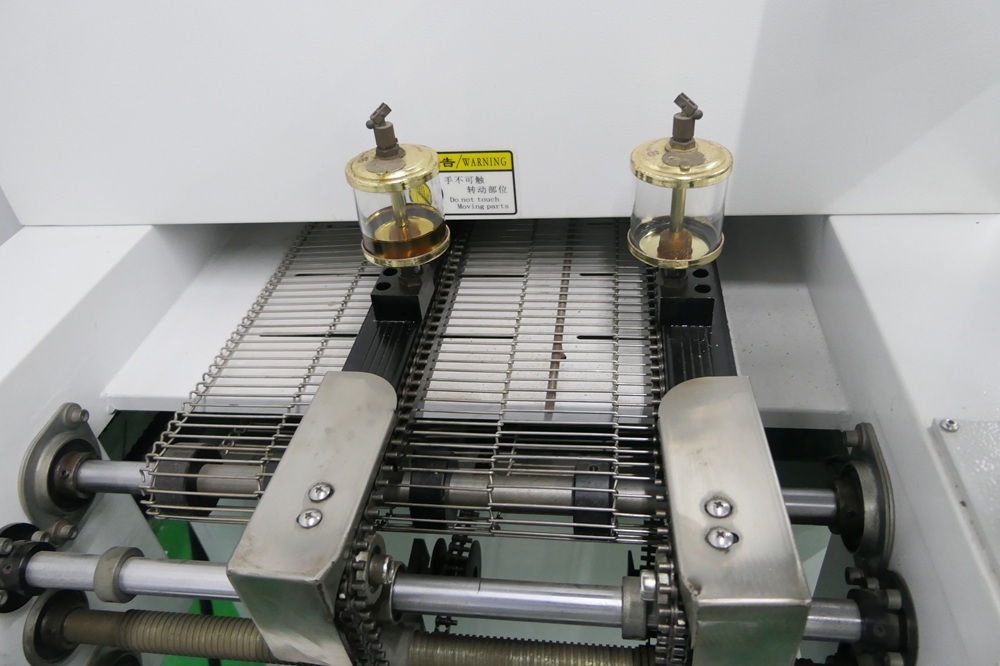

Reflow Oven Conveyorized 6 Zone is a high-performance, inline soldering system designed for consistent, lead-free and leaded PCB soldering. It features HMI + PLC control, forced hot-air convection, and a stainless-steel mesh with pin-chain conveyor system, ensuring even heat distribution and minimal board distortion.

Built for industrial electronics, automotive, and consumer product assembly lines, this six-zone reflow oven ensures superior process reliability, faster throughput, and energy-efficient performance. Its closed-loop temperature control and precision airflow design guarantee uniform soldering quality, making it an ideal solution for demanding SMT manufacturing environments.

Technical Specifications:

-

Heating Zone: 6 Top + 6 Bottom

-

Heating Zone Length: 2,400 mm

-

Dimensions: 3,800 mm 900 mm 1,650 mm

-

Weight: 1,400 kg

-

Power Supply: 440 V AC, 50 Hz, 3 Phase

-

Power Start Up: 34 kW

-

Power Operation: 8 kW

-

Heating Time: 20 Minutes

-

Control Type: HMI + PLC Control

-

Heat Type: Forced Hot-Air Convection (Top + Bottom)

-

Temperature Control: Closed-Loop PID + SSR

-

Temperature Range: Ambient 350 C

-

Temperature Accuracy: 2 C

-

Cooling: 1 Zone Cooling Fan

-

Conveyor Type: Stainless Steel Mesh Belt + Pin Chain

-

Conveyor Height: 900 mm 20 mm

-

Conveyor Speed: 0 1.8 m/min

-

Belt Width: 400 mm

-

PCB Size: 50 300 mm

-

PCB Clearance Height: 25 mm

-

Solder Type: Lead-Free / Leaded

-

Key Features

- Advanced HMI + PLC Control System

- Closed-loop PID + SSR control ensures stable, repeatable temperature regulation in every zone.

- 6-Zone Forced Hot-Air Convection Heating

- Jet-nozzle micro-circulation system ensures consistent airflow, reducing cold joints and solder voids.

- Dual Conveyor System (Mesh + Pin Chain)

- Aluminium-alloy profiles reduce vibration and distortion for high-precision soldering.

- Energy-Efficient Performance

- High thermal efficiency minimizes energy loss and reduces long-term operating costs.

- Centralized Lubrication System

- Minimizes manual maintenance and extends equipment lifespan.

- Temperature Accuracy & Stability

- Uniform top/bottom convection reduces thermal stress on sensitive components.

- Flexible Production Capability

- Supports both lead-free and leaded solder types for wide process compatibility.

Applications

Consumer electronics (mobile devices, TVs, wearables)

- Automotive ECU and sensor PCB soldering

- Industrial automation control boards

- LED lighting modules and driver boards

- IoT and communication hardware assemblies

- Research and development prototyping labs

- Contract electronics manufacturing (EMS/ODM)

Why Choose Reflow Oven Conveyorized 6 Zone?

- Ensures stable, defect-free soldering with uniform thermal profiles.

- High structural rigidity minimizes PCB distortion during reflow.

- PLC + HMI control simplifies operation and process tuning.

- Low maintenance with automatic chain lubrication system.

- Compatible with both lead-free and leaded solder types.

- Efficient power consumption for reduced operational costs.

- Ideal for SMT lines seeking repeatability and long-term reliability.

Superior Soldering Uniformity

With three top and three bottom heating zones, the oven delivers consistent soldering results across the entire PCB surface. The hot air circulation method ensures even temperature distribution while minimizing defects, making this model ideal for high-volume SMT assembly.

Effortless Operation and Control

An advanced PLC-based touchscreen interface provides control over the complete process. Operators can set programmable profiles, monitor data logs, and manage safety functions. The built-in alarm system and overheat protection guarantee reliable and secure operation.

Energy Efficiency and Robust Design

The oven is engineered for low energy consumption with a power rating of just 7.5 kW. Its sturdy mild steel frame, powder-coated finish, and forced air cooling system ensure durability, easy maintenance, and silent operation below 65 dB. Connectivity features like RS232/USB offer integration flexibility.

FAQs of Reflow Oven Conveyorized 6 Zone:

Q: How does the Reflow Oven Conveyorized 6 Zone ensure precise temperature control during the soldering process?

A: This oven utilizes PLC touchscreen control and hot air circulation to maintain accurate temperatures within 1 C, accommodating programmable profiles for varied soldering requirements. Operators can easily monitor and adjust parameters through the HMI panel.Q: What is the maximum PCB size and thickness the oven can handle?

A: The oven is designed to handle PCBs measuring up to 450 x 400 mm, with a maximum clearance of 30 mm. The conveyor width supports boards up to 400 mm, making it suitable for most SMT assembly needs.Q: When can the oven be used during PCB assembly processes?

A: The Reflow Oven is typically employed directly after solder paste application and component placement, serving as the primary soldering step in SMT production lines. It features a 20-minute start-up time, ideal for both routine and high-volume operations.Q: Where is the Reflow Oven best suited for installation and usage?

A: It is designed for installation in SMT assembly lines within manufacturing facilities. Its compact dimensions (3400 x 720 x 1280 mm), atmospheric pressure operation, and low noise level make it suitable for various industrial environments, including exporter and supplier settings.Q: What safety measures are implemented in the ovens design?

A: Safety features include overheat protection, an emergency stop, and an alarm system. These mechanisms minimize operational risks and safeguard personnel and equipment during use.Q: How does the oven benefit the PCB soldering process?

A: This conveyerized reflow oven delivers consistent, high-quality solder joints with uniform heating, while programmable recipes and automated lubrication streamline operation, enhance repeatability, and reduce manual intervention. Its optimized energy consumption helps lower operational costs.Q: What connectivity and data management options does the oven offer?

A: The oven supports RS232/USB interface connectivity for recipe programming, data logging, and integration into smart manufacturing environments. This simplifies process management and quality traceability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+