Automatic DIP Soldering Machine 14 X 18 inch

34000.0 INR/Piece

Product Details:

- Control System Semi-Automatic

- Voltage 110-215 Volt (v)

- Country Of Origin India

- Product Type Dip Soldering Machine

- Power Source Electricity

- Surface Treatment Coated

- Warranty 1 year

- Click to View more

X

Automatic DIP Soldering Machine 14 X 18 inch Price And Quantity

- 34000.0 INR/Piece

- 1 Piece

Automatic DIP Soldering Machine 14 X 18 inch Product Specifications

- 110-215 Volt (v)

- Semi-Automatic

- Electricity

- 1 year

- Industrial

- India

- Dip Soldering Machine

- Coated

Automatic DIP Soldering Machine 14 X 18 inch Trade Information

- 5-10 Days

Product Description

Automatic DIP Soldering Machine 14 X 18 by Estovir Technologies

Estovir Technologies introduces a high-performance Automatic DIP Soldering Machine 14 X 18 machine tailored for modern electronics manufacturing. With cutting-edge features and durable design, it ensures consistent soldering outcomes with minimal manual input. Whether you're scaling production or refining prototypes, this machine delivers dependable results every time.

Technical Specification

| Bath Size | 14 x 18 |

| Solder Capacity | 45 Kg |

| Power Supply | 220 V AC, 50Hz |

| Temperature Range | Upto 300c |

| Heater Power | 4.0 KW |

| Heat-up Time | 35 min |

| Bath Depth | 50 mm |

| Dimensions | 790 x 460 x 360 mm |

| Weight (without solder) | 50 Kg |

|

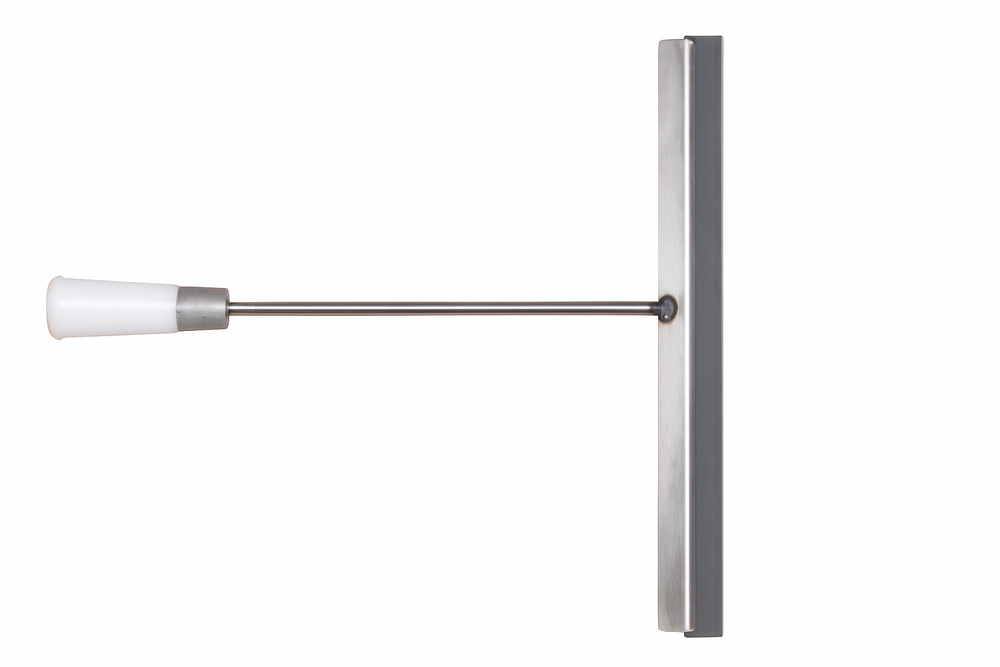

Standard Accessories | PCB Carrier 1 no |

| Scrapper 1 no | |

| L/N Key Kit 1 no | |

| Digital Temp Controller | |

| Electronic Dwell Timer | |

| PCB Depth Adjuster | |

| Multi-PCB Carrier | |

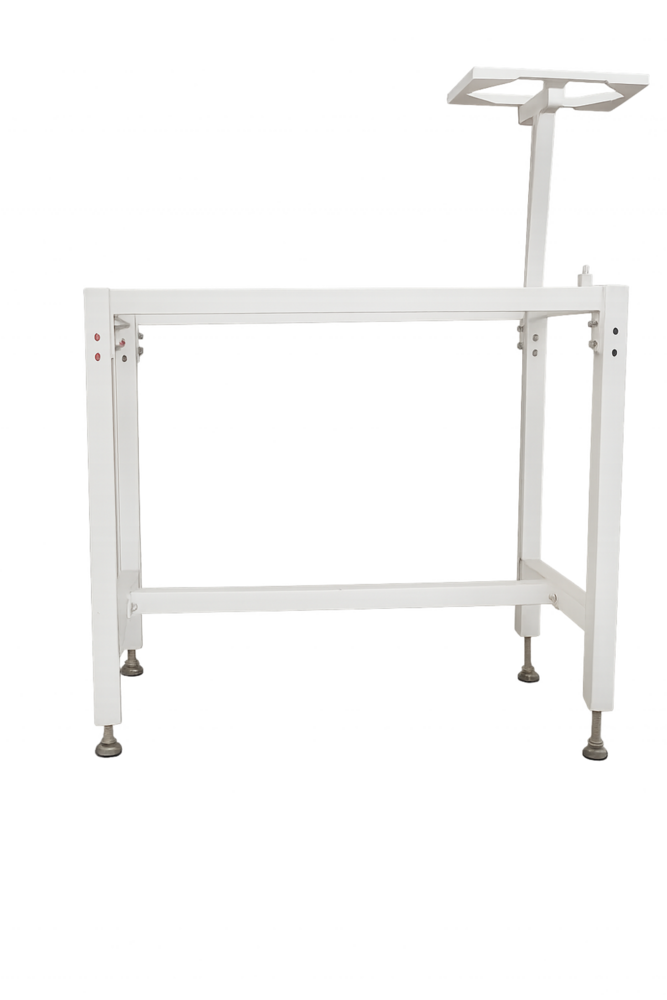

| Dip Stand (Optional-Chargeable) |

- Superior Soldering Accuracy

The system delivers precise and uniform solder joints, minimizing the risk of cold joints, solder bridges, or incomplete connections. - Enhanced Productivity

With reduced manual intervention and fast processing, it significantly increases production throughput for both small and large batch volumes. - Optimized Energy Use

Advanced thermal control and efficient power usage reduce overall operational costs without compromising performance. - Labor Cost Reduction

By automating soldering, the machine reduces dependence on manual labor, lowering staffing needs while maintaining high-quality output. - Consistent Quality Across Batches

Whether it's your first PCB or the hundredth, every board is soldered with the same precision thanks to digital timing and temperature regulation. - Low Maintenance, High Uptime

Designed with durable parts and easy access panels, this machine ensures fewer breakdowns and quick servicing, boosting uptime. - Eco-Conscious Design

With efficient energy use and minimal solder waste, it supports sustainable production practices.

Key Features of Automatic DIP Soldering Machine 14 X 18

Each unit from Estovir Technologies integrates industry-leading innovations that simplify soldering tasks and enhance reliability:

- Digital Temperature Controller

The solder bath is precisely maintained with a digital controller, ensuring consistent heat distribution and preventing thermal shock to components. This feature is crucial for sensitive or multi-layer PCBs. - Electronic Dwell Timer

Set and automate soldering time with pinpoint accuracy. - Fast Heat-Up Time

With heat-up times of just 35 minutes, the machine quickly reaches optimal temperature, reducing idle time and enabling faster job starts. - Rugged Industrial Build

Crafted from high-grade materials, the machine withstands long production hours in demanding factory environments, ensuring years of reliable performance. - Mechanical Depth Adjustment

Users can easily adjust the soldering depth to suit various PCB thicknesses. This helps accommodate diverse board layouts without needing different equipment. - Multi-Board PCB Carrier

The versatile PCB carrier allows multiple boards to be loaded at once, boosting efficiency in batch soldering without compromising quality. - Compact Footprint

Despite its powerful capabilities, the machine fits neatly in most workspaces, making it suitable even for smaller production units or labs. - Low Operating Noise

Designed for quiet operation, it maintains a safe and comfortable working environment for technicians and operators.

Automatic DIP Soldering Machine 14 X 18 Applications

- Consumer electronics manufacturing

- LED lighting assemblies

- Automotive electronics

- Telecommunication equipment

- Power supply units

- R&D labs and prototyping centers

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email