MI Line Motorized Double-Side Working Conveyor 7.3 Mtr (24 feet )

Product Details:

- Surface Finish Smooth

- Features Good Quality

- Voltage 110-215 Volt (v)

- Warranty 1 year

- Usage & Applications Industrial

- Click to View more

MI Line Motorized Double-Side Working Conveyor 7.3 Mtr (24 feet ) Price And Quantity

- 1 Number

- 265000 INR/Inch

MI Line Motorized Double-Side Working Conveyor 7.3 Mtr (24 feet ) Product Specifications

- 1 year

- Industrial

- Good Quality

- 110-215 Volt (v)

- Smooth

MI Line Motorized Double-Side Working Conveyor 7.3 Mtr (24 feet ) Trade Information

- 5-10 Days

Product Description

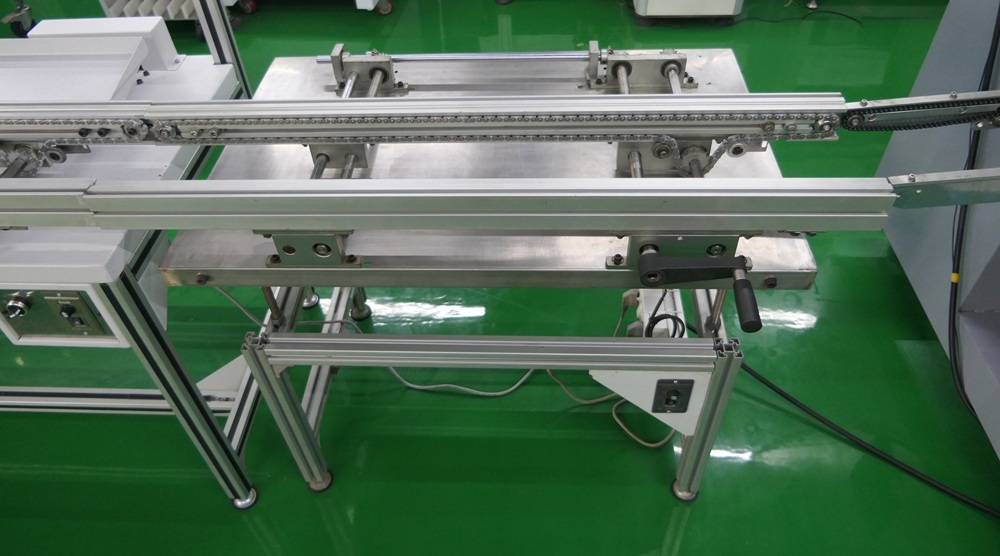

MI Line Motorized Double-Side Working Conveyor 7.3 Mtr (24)

Overview of MI Line Motorized Double-Side Conveyor 7.3 Mtr (24)

In this conveyor system, PCBs are transported on a chain conveyor with secure edge guidance. Operators on both sides sequentially insert designated components into their respective positions, ensuring faster and more balanced production. By the end of the conveyor line, boards are fully populated and ready for soldering. Adjustable channels support various PCB sizes, while smooth transfer and secure handling ensure consistent quality. Built with a strong aluminium (4040) or powder-coated steel frame, the MI Line Double-Side Conveyor provides an ergonomic working height (900 mm 25 mm), adjustable bin trays on both sides, and variable speed control (0.751.7 m/min) driven by a 3-phase induction motor. Its ESD-safe design, operator-centric features, and fire-hazard-free construction make it ideal for high-volume production across automotive, medical device, and consumer electronics sectors.

Technical Specifications MI Line Motorized Double-Side Working Conveyor 7.3 Mtr (24)

| Specification | Details | |||||||||||||||||

| Conveyor Type | Conveyor Length | Conveyor Height | Working Height | PCB Width Range | Structure Material | Chain Type | Channels | Working Platform | Front & Rear Channels | Bin Trays | Lighting | Display Board | Conveyor Speed | Control Panel | Motor | Safety Features | Fire Safety | Key Features of MI Line Motorized Double-Side Working Conveyor 7.3 Mtr (24)

Why Choose MI Line Motorized Double-Side Working Conveyor 7.3 Mtr (24) from Estovir TechnologiesSelecting the right conveyor system is essential for maintaining productivity, reducing downtime, and ensuring long-term operational reliability. At Estovir Technologies, we deliver robust engineering, operator-focused designs, and comprehensive support that align perfectly with modern PCB assembly needs.

|

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free