Manual Cut and Bend Machine For Taped Axials

Product Details:

- Power 200 Watt (w)

- Surface Treatment Galvanized

- Dimension (L*W*H) 1800 X 1200 X 160 Millimeter (mm)

- Weight (kg) 200-400 Kilograms (kg)

- Color White

- Click to View more

Manual Cut and Bend Machine For Taped Axials Price And Quantity

- 12500.0 INR/Piece

- 1 Piece

- 11500.00 - 11500.00 INR/Piece

Manual Cut and Bend Machine For Taped Axials Product Specifications

- White

- 1800 X 1200 X 160 Millimeter (mm)

- 200 Watt (w)

- Galvanized

- 200-400 Kilograms (kg)

Manual Cut and Bend Machine For Taped Axials Trade Information

- 15 Piece Per Month

- 6 Days

- All India

Product Description

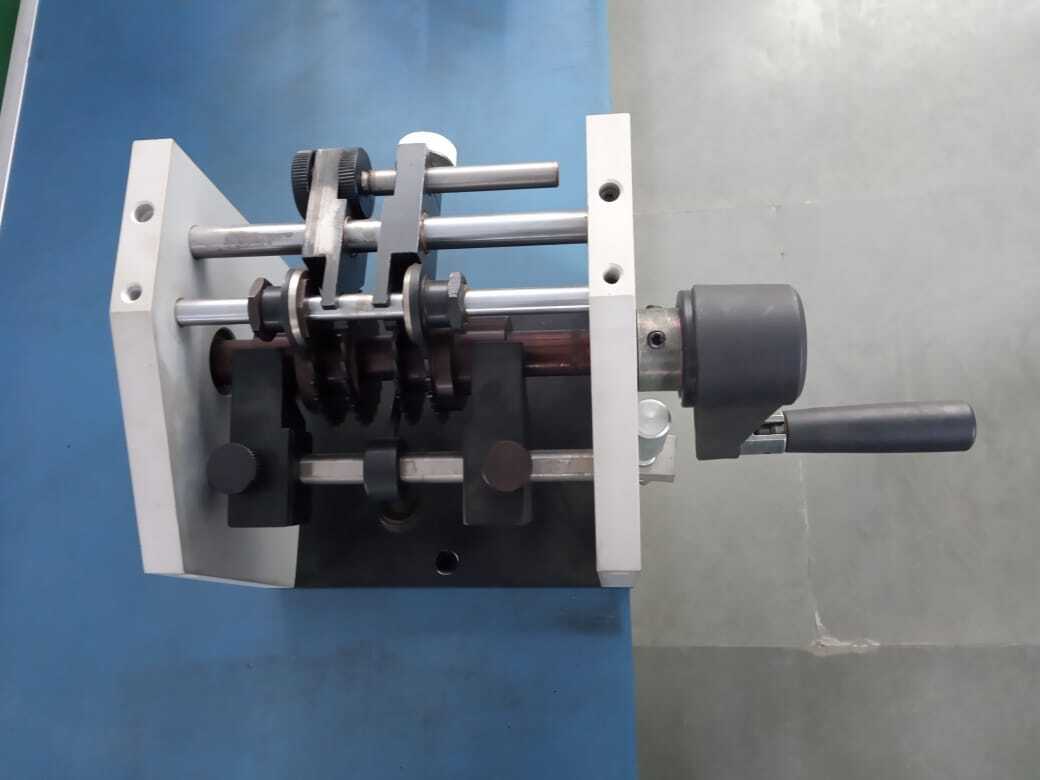

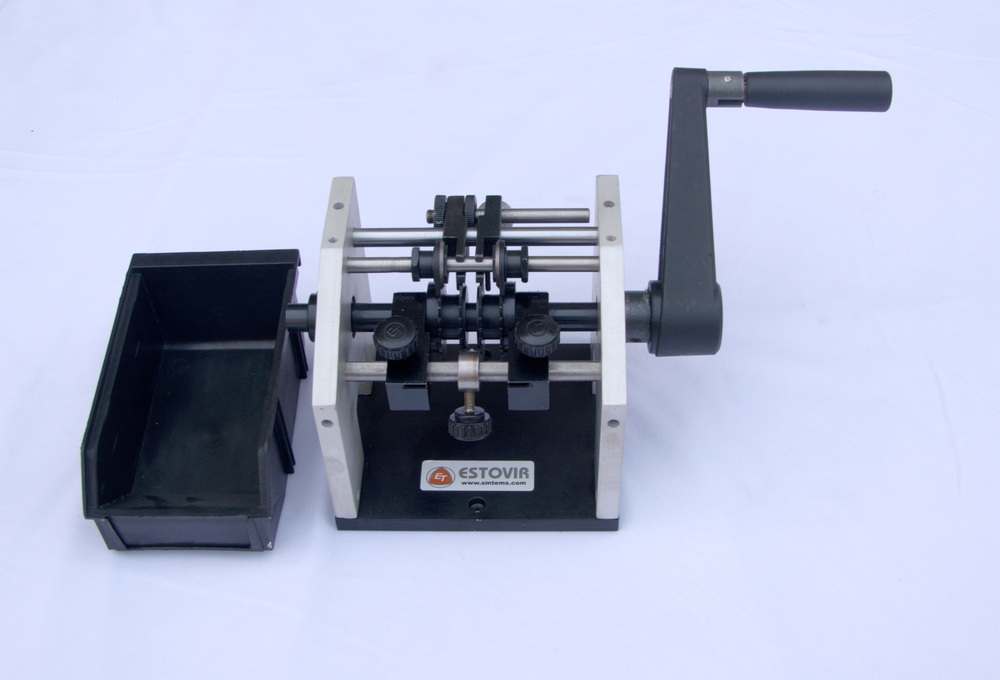

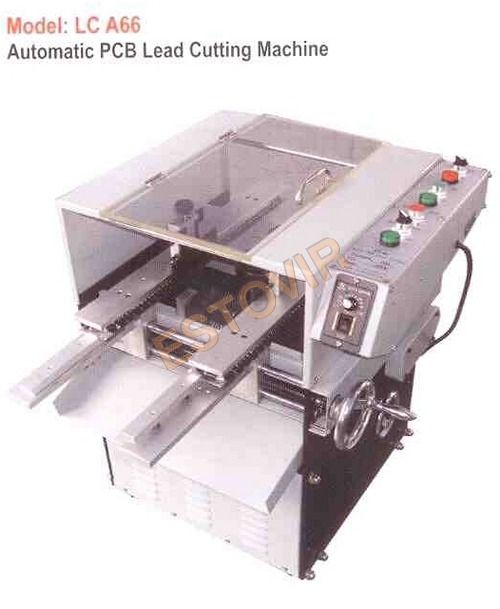

MAP 860 Manual Cut & Bend Machine for Taped Axial Components Precision & Efficiency by Estovir Technologies

The MAP 860 Manual Cut & Bend Machine is a high-precision solution designed for efficient cutting and bending of taped axial components in electronics manufacturing. Engineered by Estovir Technologies, this compact and ergonomic machine ensures consistent, high-quality component preparation, optimizing production workflows while minimizing waste.

Key Features:

- Precision Cutting & Bending High-accuracy blade system for uniform cuts with adjustable bending angles for tailored shaping.

- Ergonomic & Compact Design Manual operation reduces operator fatigue, with a space-saving footprint for various workstation setups.

- Versatile Compatibility Supports taped axial components with lead diameters up to 0.8 mm softwire and features adjustable guides for different tape widths.

- Durable & Low Maintenance Built with industrial-grade materials, ensuring longevity and easy access for maintenance.

- Optimized Throughput Streamlined manual operation enhances processing speed, delivering consistent results and reducing rework.

Ideal for PCB assembly lines, electronics manufacturing, and prototype development, the MAP 860 is a reliable, cost-effective solution for precision component handling.

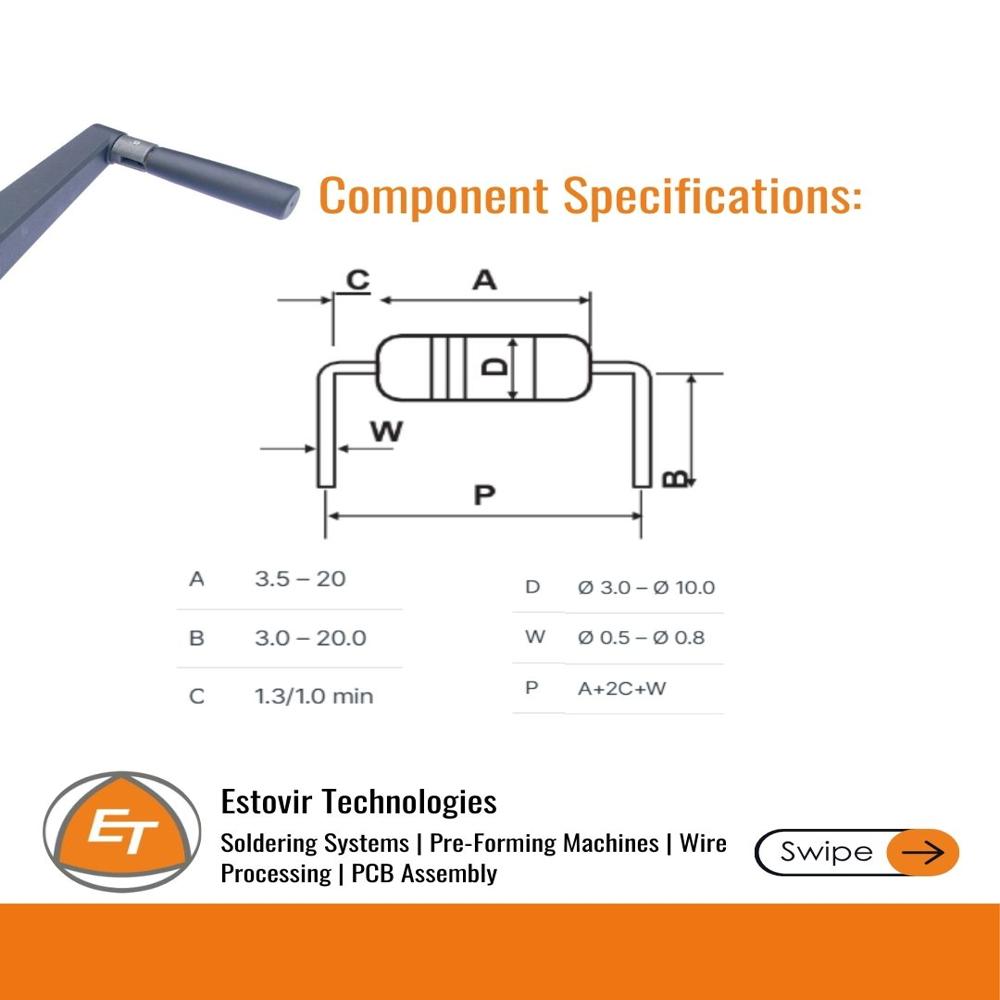

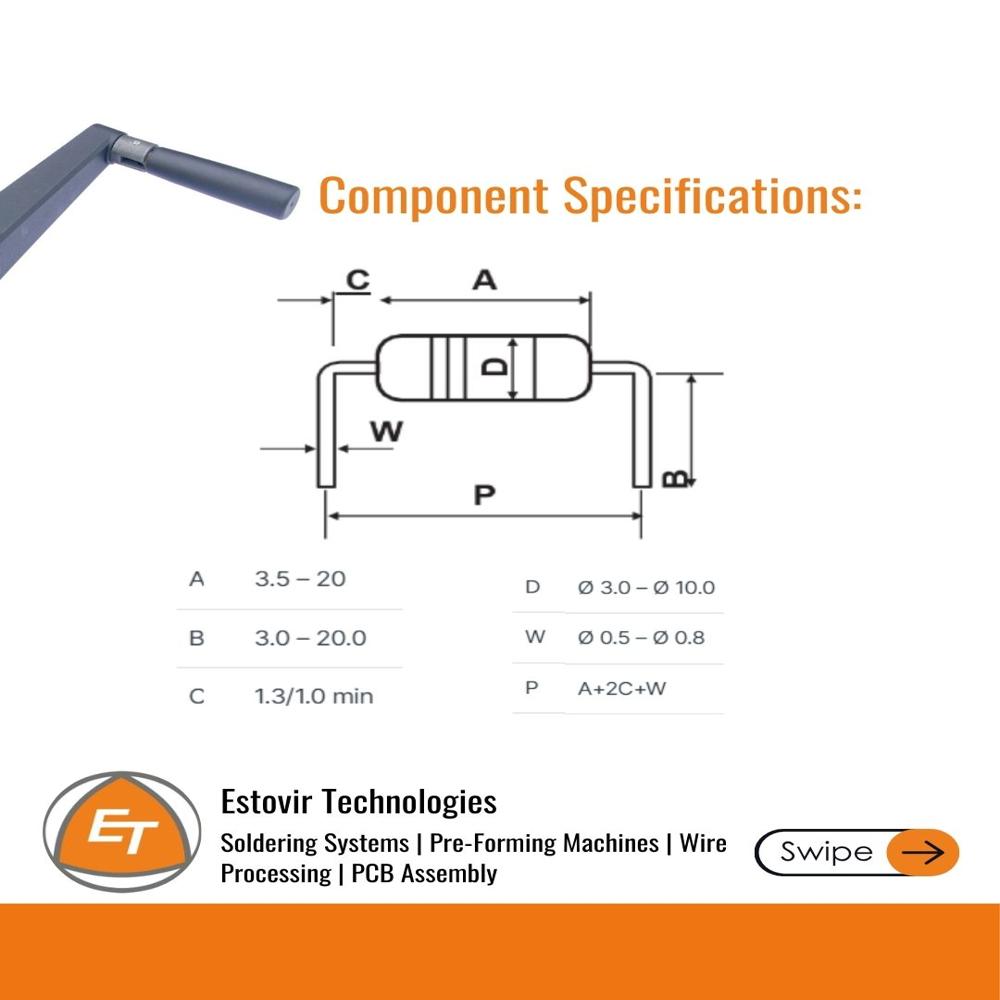

Technical Specifications:

o Model: MAP 860

o Component Type: Taped Axial

o Cutting Length Range: 3mm 20mm

o Bending Angle Range: 0 90 (adjustable)

o Tape Width Compatibility: 26mm 56mm

o Operation Mode: Manual

o Material: High-grade steel and industrial polymers

o Output Capacity: 10,000 24000 pcs/hr

o Dimensions: L-160mm, W-160mm, H-155mm

o Weight: 3Kg

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free