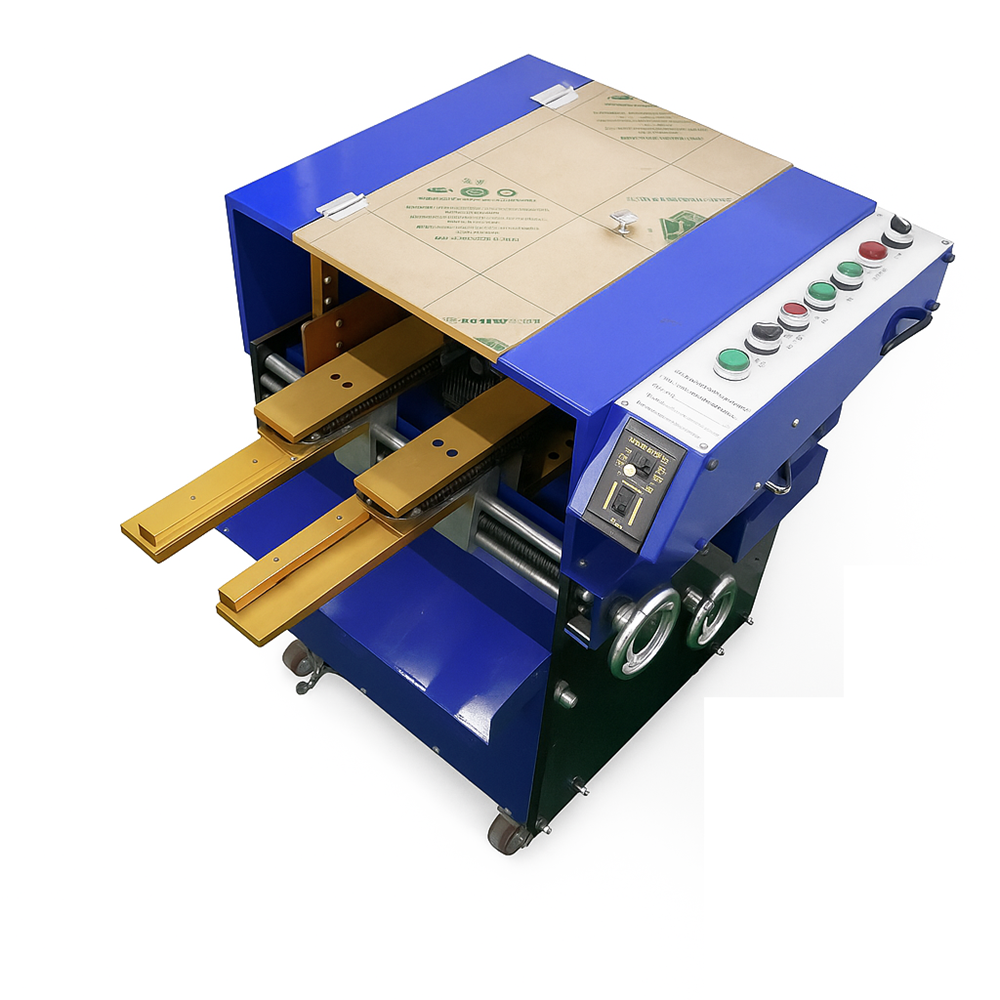

Automatic PCB Lead Cutting Machine LC A66

185000 INR/Number

Product Details:

- Features Durable

- Voltage 220V AC Volt (v)

- Country Of Origin India

- Cooling System Air Cooling

- Drive Electric

- Frequency 50 Hz Hertz (HZ)

- Control System Fully Automatic

- Click to View more

X

Automatic PCB Lead Cutting Machine LC A66 Price And Quantity

- 185000 INR/Number

- 1 Number

Automatic PCB Lead Cutting Machine LC A66 Product Specifications

- Air Cooling

- Electric

- India

- 220V AC Volt (v)

- Automatic

- Durable

- Automatic PCB Lead Cutting

- 740 X 565 X 755 mm Millimeter (mm)

- Automatic PCB Lead Cutting Machine

- Metal Frame

- 50 Hz Hertz (HZ)

- Fully Automatic

Product Description

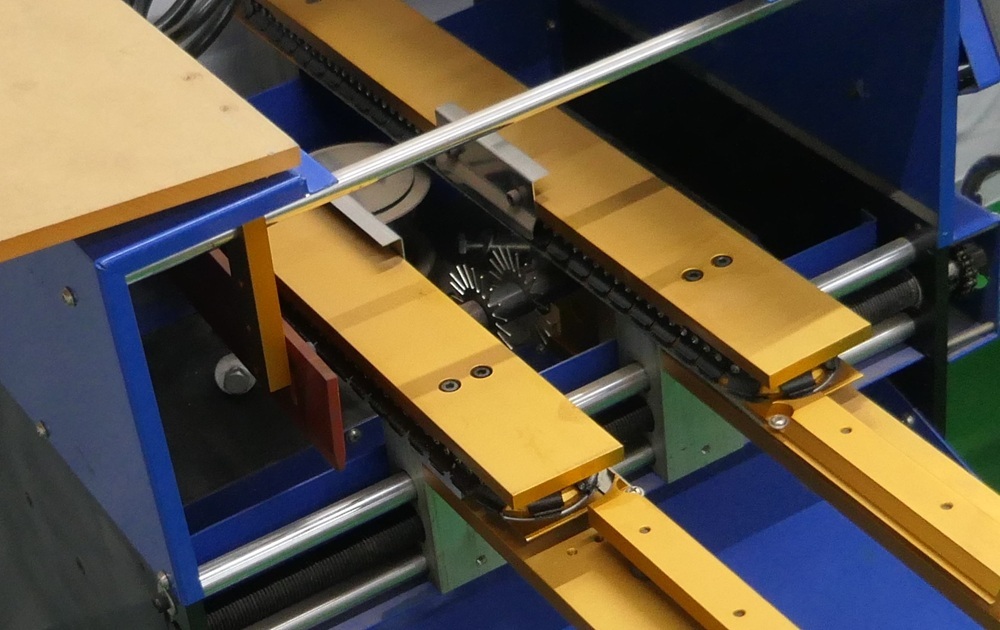

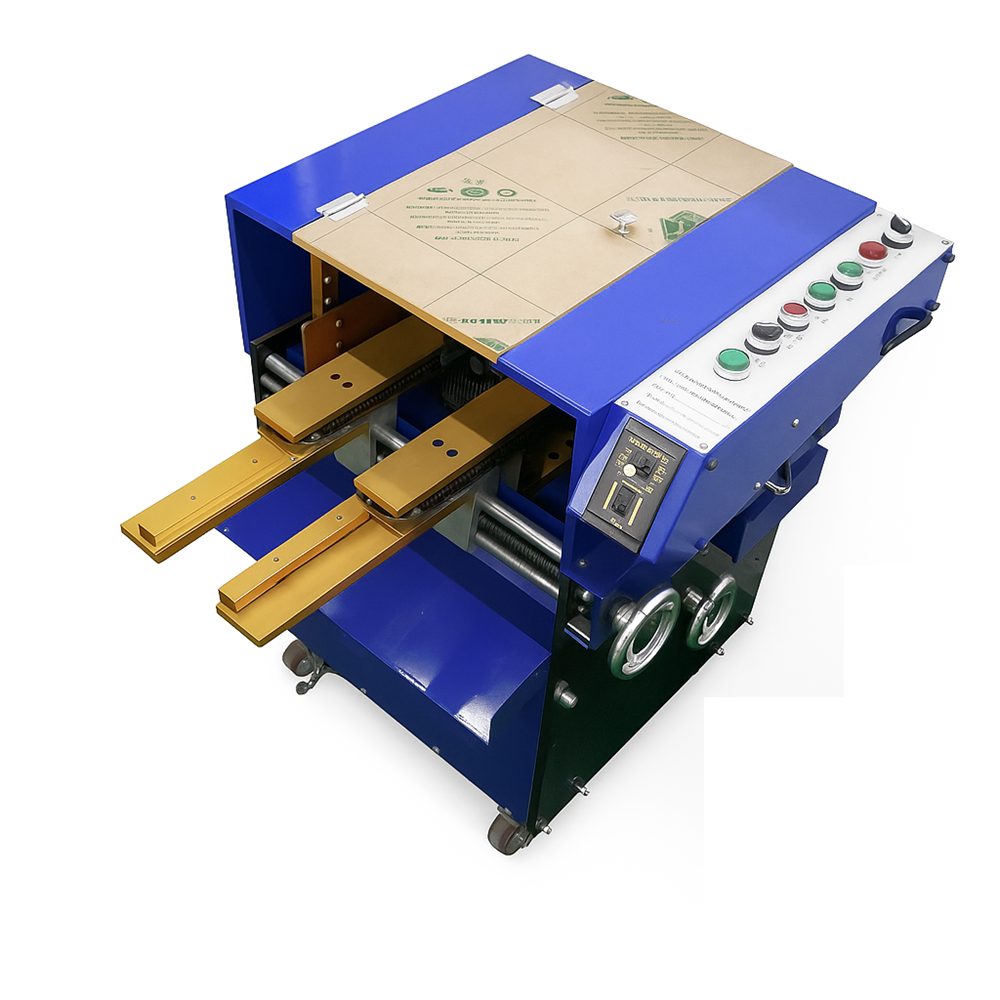

Automatic PCB Lead Cutting Machine LC A66The LC A66 Automatic PCB Lead Cutting Machine by Estovir Technologies is engineered for post-solder lead trimming in high-volume PCB assembly lines. Using a conveyor chain mechanism, the machine automatically clamps and transports PCBs towards a high-speed tungsten carbide blade (LC TC 250) for accurate and uniform lead cutting. Built with a wrap prevention device, it ensures damage-free processing, making it the perfect choice for electronics, consumer goods, and automotive PCB manufacturing. With a spindle speed of 4500 RPM and adjustable conveyor control, the LC A66 delivers unmatched speed, safety, and precision.

- Model: LC A66

- Operation Type: Automatic (conveyor-based feed)

- Cutting Blade: LC TC 250 Tungsten Carbide (250 mm OD, 70 mm ID, Thickness 3.5 mm)

- PCB Thickness: 0.8 to 2.5 mm

- Max PCB Size: 500 to 300 mm

- Cutting Height: 0.6 mm minimum

- Spindle Speed: 4500 RPM

- Main Motor Power: HP

- Conveyor Speed: 0 to3 m/min (adjustable)

- Power Supply: 220V AC, 50 Hz

- Dimensions: 740 X 565 X 755 mm

- Machine Weight: 115 Kg

Key Features of Automatic PCB Lead Cutting Machine LC A66

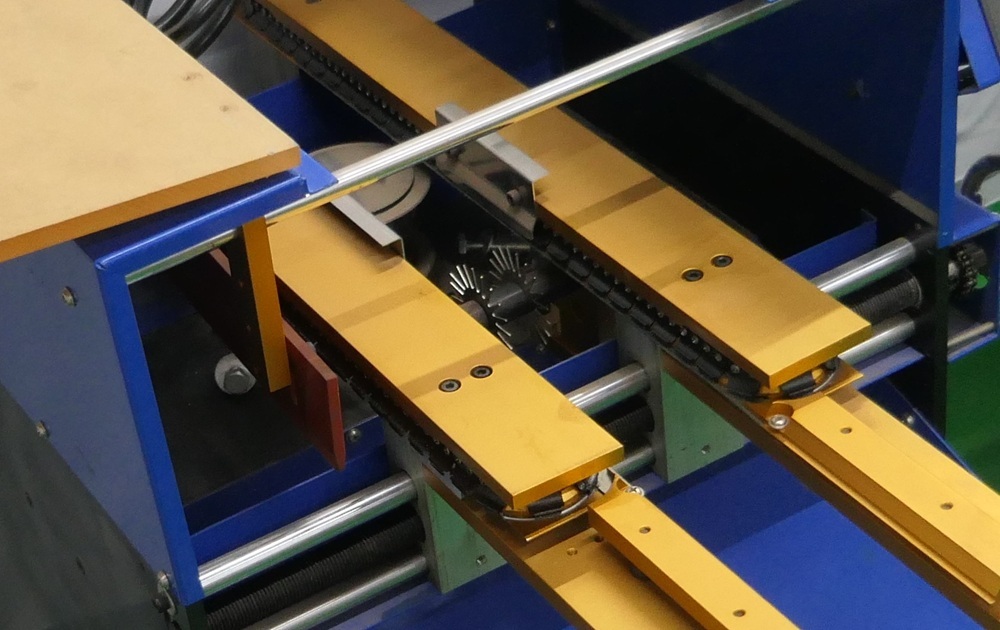

- Automatic PCB Transportation

- Conveyor chain clamps securely hold and transport PCBs into the cutting blade.

- Reduces manual handling and boosts efficiency in production lines.

- High-Speed Tungsten Carbide Blade (LC TC 250)

- Equipped with a 250 mm outer diameter, 70 mm ID, 3.5 mm thickness blade.

- Blades are re-sharpenable, ensuring long-term cost savings and consistent performance.

- Wrap Prevention System

- Special device prevents bending or damage to PCBs during cutting.

- Guarantees clean finishing, even on thin and delicate boards.

- Flexible & Adjustable Operation

- Conveyor speed adjustable between 0 to 3 m/min for different workloads.

- Cutting height as low as 6 mm, suitable for multiple PCB thicknesses (0.8 to 2.5 mm).

- Durable Industrial Build

- Weighing 115 kg, it is designed for continuous factory-floor operation.

- Rugged body ensures stability and vibration-free cutting.

Why Choose LC A66?

- Boosts production speed with fully automated PCB handling.

- Guarantees precise, uniform lead cutting for a professional finish.

- Prevents PCB damage with integrated wrap-prevention system.

- Compact, space-saving design ideal for industrial production lines.

- Uses reliable LC TC 250 tungsten carbide blades, ensuring durability.

- Trusted by global electronics manufacturers for quality and efficiency.

Applications of Automatic PCB Lead Cutting Machine LC A66

- PCB assembly lines for consumer electronics and LED products.

- Automotive electronic module production.

- High-volume industrial PCB manufacturing.

- Contract electronic assembly services.

Maintenance & Blade Information

- Blade Maintenance to The LC TC 250 tungsten carbide blade can be re-sharpened using the LC G250 blade sharpening machine, ensuring consistent long-term performance.

- Low Maintenance Design to Built with minimal moving parts and a rugged frame, the LC A66 requires very little upkeep.

- Operator Safety to Manual push-handle feeding ensures safe PCB handling during operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email