Cutting Blade Sharpening Machine

58000 INR/Unit

Product Details:

- Drive Electric

- Voltage 220V AC Volt (v)

- Accuracy 100 %

- Frequency 50 Hertz (HZ)

- Country Of Origin India

- Power Source Electricity

- Operating Type Semi Automatic

- Click to View more

X

Cutting Blade Sharpening Machine Price And Quantity

- 1 Unit

- 58000 INR/Unit

Cutting Blade Sharpening Machine Product Specifications

- Other

- Industrial

- Electric

- 100 %

- 220V AC Volt (v)

- 50 Hertz (HZ)

- India

- gray

- Semi Automatic

- 220 Volt (v)

- Electricity

- 125 Kilograms (kg)

Cutting Blade Sharpening Machine Trade Information

- 15 Unit Per Month

- Week

- extra at actual

- All India

Product Description

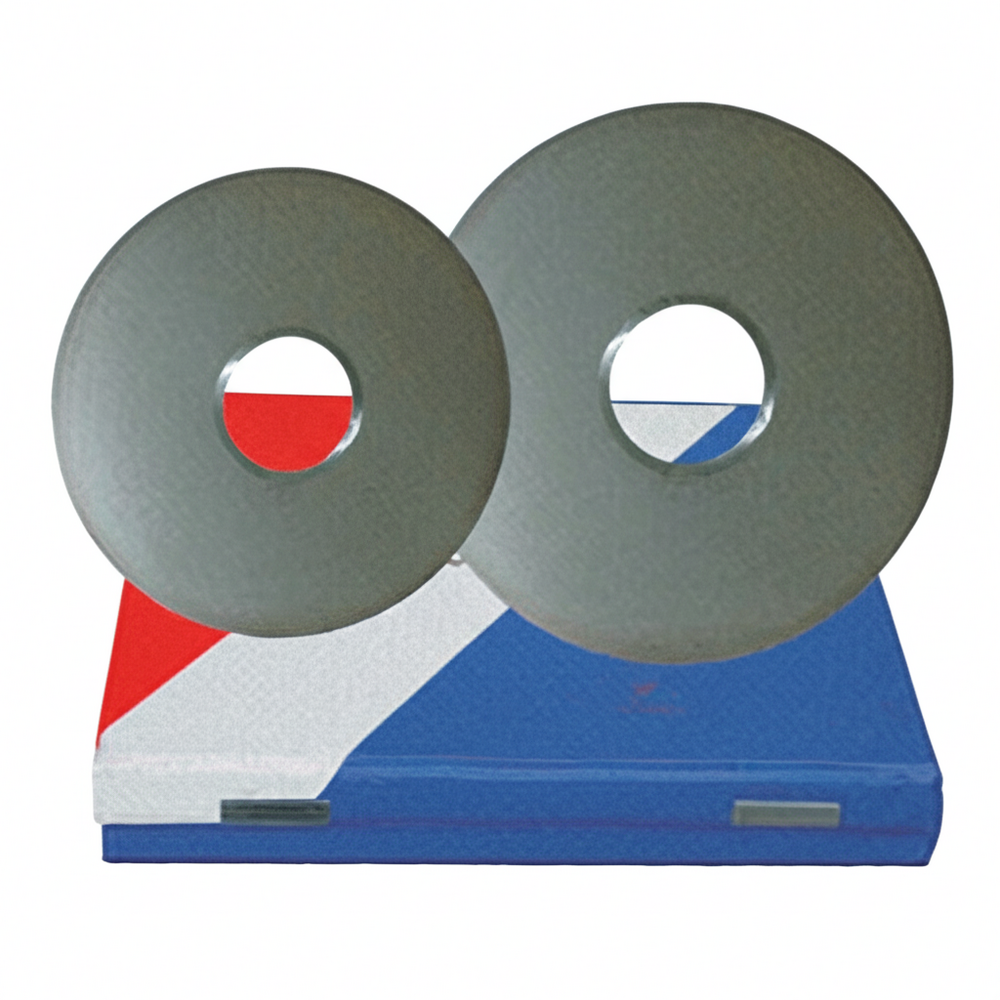

Blade Sharpening Machine ï LC G250 by Estovir

TheBlade Sharpening MachineïLC G250byEstovir Technologiesis engineered to deliver unmatched precision in maintaining and restoring the sharpness ofTungsten Carbide bladesïLC TC 250used in PCB lead cutting machines (like LC A66 & LC M66). Dull blades can cause uneven trimming, PCB surface damage, and increased downtime.

Technical Specification

| Specification | Details |

| Model | LC G250 |

| Blade Compatibility | LC TC 250 Tungsten Carbide (250 mm OD, 70 mm ID, 3.5 mm thickness) |

| Grinding Spindle Speed | 4500 RPM |

| Operation Type | Manual Feed Sharpening |

| Motor Power | HP |

| Power Supply | 220V AC, 50 Hz |

| Machine Weight | 120 Kg |

| Frame Build | Heavy-duty, vibration-free structure |

Key Features ï Blade Sharpening Machine LC G250

- Compatible with Tungsten Carbide Blades

- Specially designed to sharpen tungsten carbide blades used in PCB lead cutting and other industrial cutting machines.

- Restores the original sharp cutting edge, reducing frequent blade replacement costs and downtime.

- High-Speed Precision Grinding

- Powered by a4500 RPM spindlefor smooth, uniform, and accurate sharpening.

- Ensures clean, sharp edges for consistent PCB trimming while preventing overheating and blade damage.

- Heavy-Duty & Vibration-Free Design

- Built with arigid 120 Kg framefor stability and long service life.

- Industrial-grade structure supports continuous operation with accuracy and durability.

- Cost-Effective Blade Management

- Extends blade life to minimize downtime and maximize ROI.

- Ensures consistent cutting performance while saving money on frequent blade purchases.

- Simple & Operator-Friendly

- Manual feed design for easy handling and quick setup.

- Requires minimal training, reduces operator skill dependency, and ensures easy maintenance.

- Easy maintenance with minimal training.

Applications of Blade Sharpening Machine ï LC G250

- PCB Assembly Unitsï For maintaining sharp blades in continuous trimming operations.

- Consumer Electronics Manufacturingï Ensures smooth cutting in large-scale device assembly.

- LED Board Productionï Keeps blade edges sharp for delicate LED PCBs.

- Automotive Electronicsï Maintains blade sharpness for high-density, soldered boards.

- Industrial Electronicsï Supports precision cutting requirements in large-scale factories.

Why Choose LC G250?

- Maximizes blade life with professional-grade sharpening.

- Maintains cutting precision for high-volume production.

- Robust design built for industrial reliability.

- Cuts down recurring expenses on blade replacement.

- A trusted solution from Estovir Technologies, a leader in PCB assembly machinery.

Maintenance & Blade Care of Blade Sharpening Machine ï LC G250

- Regular sharpening maintains blade sharpness and prevents PCB damage.

- LC TC 250 blades can be re-sharpened multiple times without compromising quality.

- Proper cleaning and careful handling during installation ensure maximum blade performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free