Automatic Wire Cutting & Stripping Machine

Product Details:

- Wire Material Other

- Inlet Diameter AWG 16 to 32 Millimeter (mm)

- Outlet Diameter AWG 16 to 32 Millimeter (mm)

- Insulation Material Other

- Voltage 220V AC, 50 Hz Volt (v)

- Power 220 V AC, 50 Hz, 200W Volt (v)

- Dimension (L*W*H) L-570mm W- 380mm H-440mm Millimeter (mm)

- Click to View more

Automatic Wire Cutting & Stripping Machine Price And Quantity

- 1 Unit

- 138000 INR/Piece

Automatic Wire Cutting & Stripping Machine Product Specifications

- Other

- 220V AC, 50 Hz Volt (v)

- Other

- 220 V AC, 50 Hz, 200W Volt (v)

- AWG 16 to 32 Millimeter (mm)

- Gray

- 12 Month

- L-570mm W- 380mm H-440mm Millimeter (mm)

- 40 Kg Kilograms (kg)

- AWG 16 to 32 Millimeter (mm)

- Other

Automatic Wire Cutting & Stripping Machine Trade Information

- 15 Unit Per Month

- Week

- Extra At Actual

- All India

Product Description

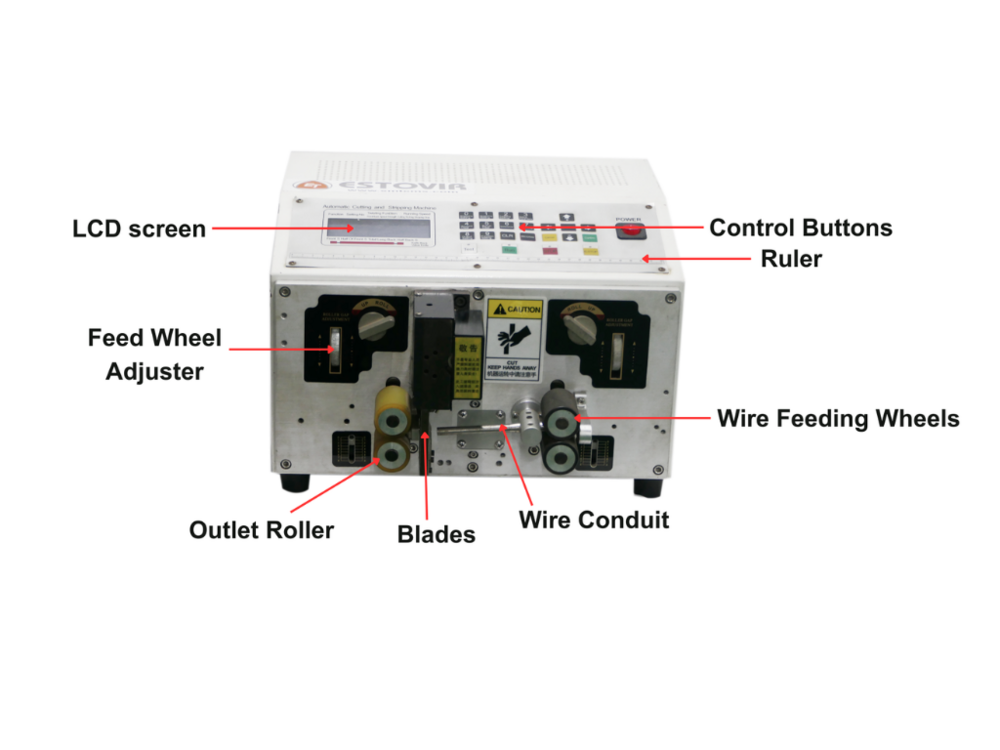

Digital Wire Cutting & Stripping Machine AWS 220

Overview of Digital Wire Cutting & Stripping Machine AWS 220

The Digital Wire Cutting & Stripping Machine AWS 220 by Estovir Technologies is a next generation high efficiency solution for modern industrial wire processing. Designed to deliver speed, accuracy, and reliability, it eliminates manual errors while streamlining production. As an automatic wire cutting and stripping machine, it ensures consistent results across high volume operations, saving time and reducing labor costs.

With support for wire diameters from AWG 16 to 32, the AWS 220 handles cutting lengths from 0.1 mm up to 9999 mm and stripping lengths from 0.1 mm to 99 mm. Its dual wire feeding mechanism allows simultaneous cutting and stripping of two wires, doubling productivity. Equipped with hard tungsten steel blades and a 4 drive system, it ensures long service life and repeatable accuracy.

Compact in design (450 480 340 mm, 32 kg) yet robust in build, the AWS 220 integrates smoothly into electronics assembly, cable harness manufacturing, and industrial automation. With processing speeds up to 3000 to 8000 pcs/h, it is a reliable choice for industries that demand efficiency, precision, and scalability.

Key Features of Digital Wire Cutting & Stripping Machine AWS 220

High Speed Precision

-

Flexible Cutting Range: Adjustable from 1 to 9999 mm, suitable for both small wires and long cable production.

-

Accurate Stripping: Stripping length from 1 to 99 mm, compatible with multiple insulation types.

Dual Wire Operation

-

Simultaneous Cutting: Can process two wires at once, significantly improving throughput.

-

Uniform Results: Maintains high accuracy across all wires, even at maximum speed.

Durability and Compact Design

-

Strong Build: Uses hard tungsten steel blades and a 4 drive system for stable and long lasting performance.

-

Space Saving Design: Lightweight and compact, easy to install in production lines.

Energy Efficient Performance

-

Low Power Use: Operates on 220V AC single phase supply, ensuring energy savings.

-

Reduced Maintenance: Designed with durable components to minimize downtime.

User Friendly Digital Controls

-

Easy Configuration: Simple digital panel for adjusting length, stripping depth, and processing speed.

-

Operator Comfort: Automated process reduces manual fatigue and errors.

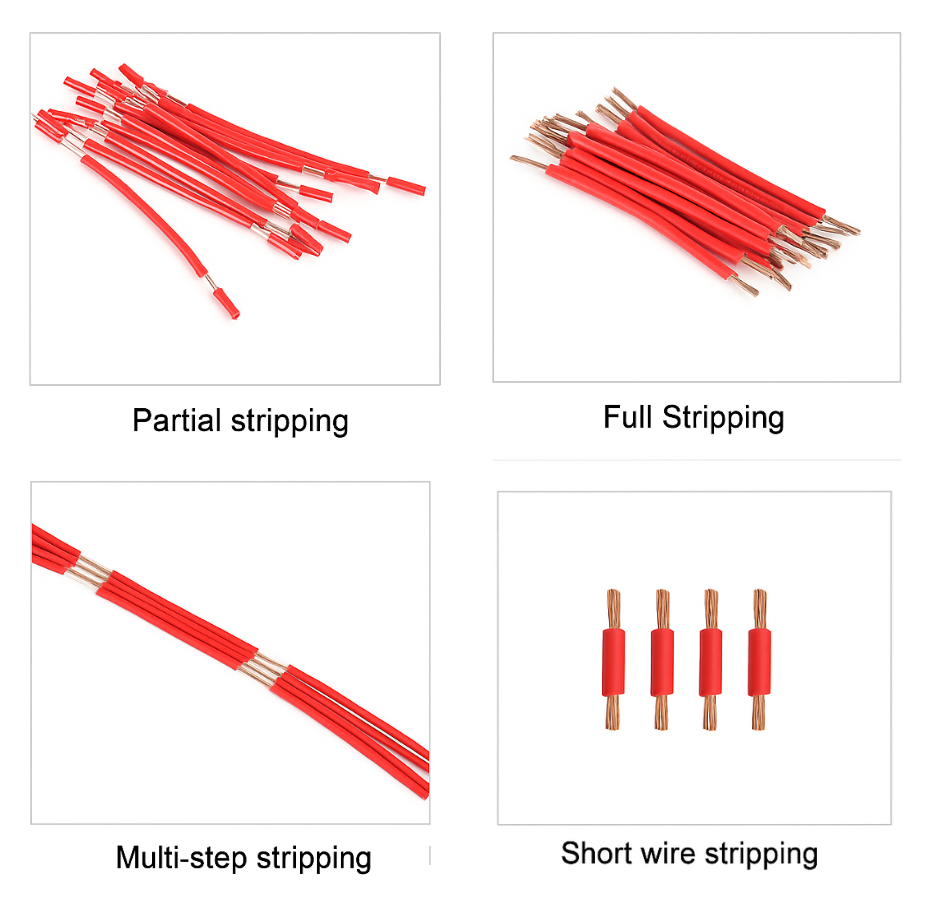

Half Stripping Capability

-

Partial Insulation Removal: Supports half stripping for crimping, soldering, and specialized assembly requirements.

-

Higher Flexibility: Eliminates the need for manual adjustments in multi step production setups.

Multiprocessing Functionality

-

Process Multiple Wire Types: Handles different wire materials and lengths within a single cycle.

-

Improved Efficiency: Minimizes downtime by enabling versatile operations in continuous production.

-

Applications of Digital Wire Cutting & Stripping Machine AWS 220

The AWS 220 is widely used in industries where accuracy, speed, and consistency are critical for productivity. Its versatility makes it suitable for a range of applications, from electronics to heavy industrial manufacturing.

-

Electronics Assembly Lines: Ensures reliable wire cut and strip operations for PCB connections and soldering.

-

Cable Manufacturing and Harness Production: Automates wire preparation for efficient large scale harness assembly.

-

Industrial Wire Processing: Handles PVC and glass fibre cables with precision.

-

Automation and Precision Work: Provides accuracy in both manual assembly and automated systems.

-

Mass Production Environments: Boosts throughput with dual wire operation and multiprocessing.

-

Why Choose AWS 220

By selecting the AWS 220, manufacturers gain a high performance wire cutting and stripping machine that delivers both reliability and productivity. Backed by Estovir Technologies expertise, it is a trusted tool for industries worldwide.

-

Proven Performance: Delivers high speed accurate results in demanding production environments.

-

Durability Assured: Built with strong materials and tungsten steel blades for long term reliability.

-

Compact and Efficient: Provides maximum output with minimal floor space.

-

Advanced Features: Includes dual wire operation, half stripping, and multiprocessing for flexibility.

-

Full Support: Backed by expert technical assistance and after sales service.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free